NODE

NODE

DIGITAL.

NETWORKED.

TRANSPARENT.

DIGITAL.

NETWORKED.

TRANSPARENT.

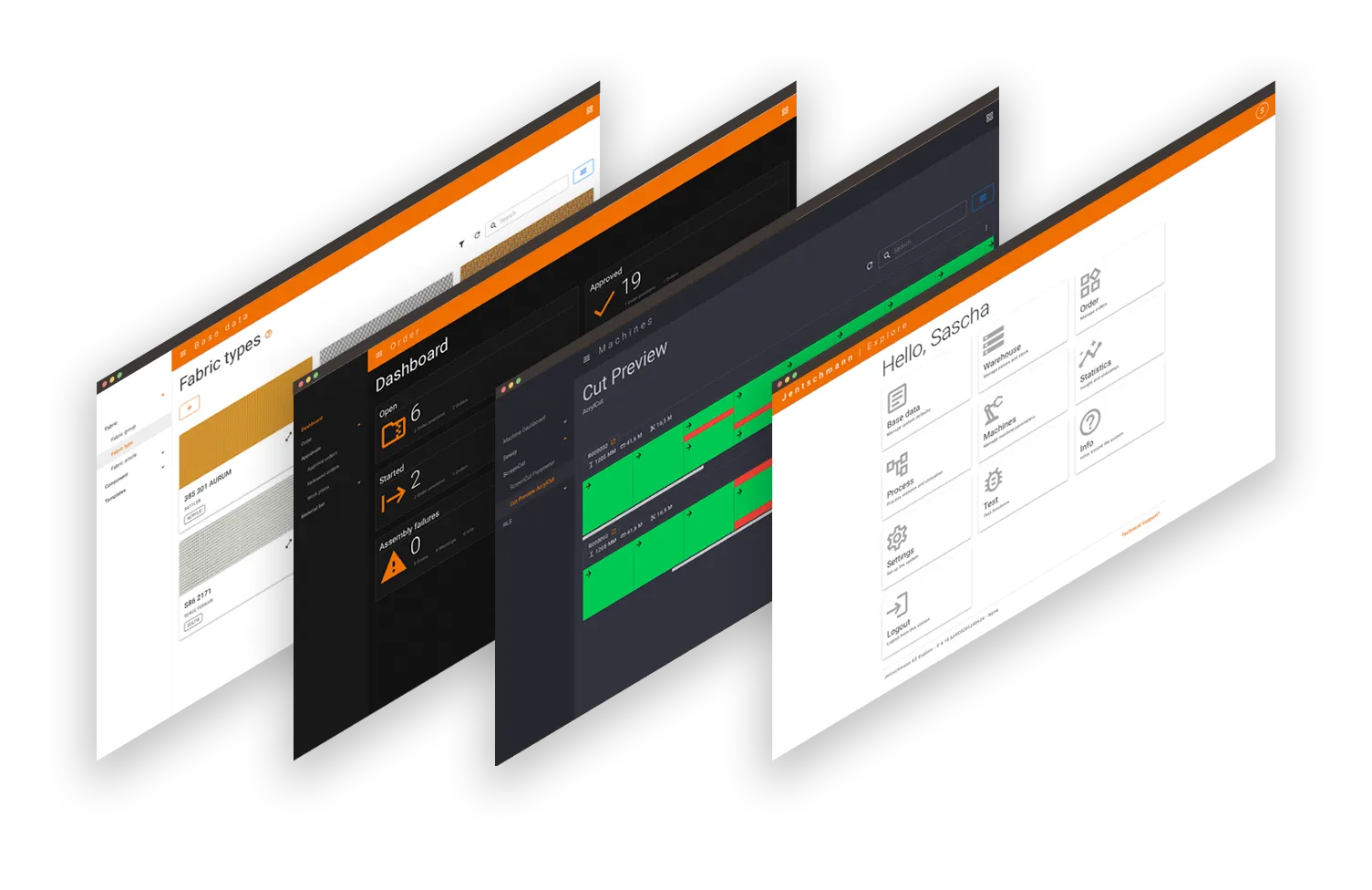

Your intelligent MES system for your production

Optimize your production with our specialized NODE Manufacturing Execution System (MES). Our system offers you real-time monitoring, complete transparency and efficient control of all production processes. It ensures the highest quality while conserving resources and reducing waste. Increase the efficiency and sustainability of your production with our innovative MES solution, which is specially tailored to the requirements of the sun shading industry. Set new standards in production performance and delight your customers with first-class products.

Incoming goods

Scan barcodes/QR codes: Each roll/component is scanned to match the delivery information with the order data in the system.

Delivery reconciliation: The MES checks the delivery against the purchase order to ensure that the quantity and type of goods delivered are correct. If there are any discrepancies, a report is created and the purchasing department is notified.

Label printing: For unmarked goods, the MES prints labels with all the necessary information (e.g. article number, batch number, production date).

Inventory management

Storage rack allocation: The MES allocates the optimum storage rack for each item based on criteria such as item type, size, weight and stock availability.

Real time inventory management: The MES updates the stock level in real time as soon as the goods are put away. This ensures that the current stock is correctly displayed at all times.

ERP synchronization: All inventory data is synchronized with the ERP system to mark orders as complete and inform departments of goods flows.

Planning

ERP integration: Ensures seamless integration with ERP systems to ensure consistent data and uniform planning.

Detailed planning and scheduling: Enables the creation of detailed production plans, taking into account all resources and capacities.

Demand calculation: Determines the demand for materials and components and compares it with the current stock. Automated messages are sent in the event of shortages.

Production

Digital order paper: All necessary information for the individual process step can be called up digitally. Images, PDFs, videos and work instructions can also be integrated.

Order tracking: Tracks the progress of production orders in real time to view the status of each order at any time.

Shop floor communication: Supports direct communication between planning and production to pass on changes and instructions in real time.

Pick & Place by Light systems help users to keep track of their tasks at all times.

Analysis

Throughput times: Continuous tracking of production times means that all throughput times are collected, which in turn is used to plan orders.

Production reports: Generates detailed reports on production performance, capacity utilization and efficiency.

Traceability: The data generated is recorded down to the lowest level at all times and can be viewed years later.

Incoming goods

Scan barcodes/QR codes: Each roll/component is scanned to match the delivery information with the order data in the system.

Delivery reconciliation: The MES checks the delivery against the purchase order to ensure that the quantity and type of goods delivered are correct. If there are any discrepancies, a report is created and the purchasing department is notified.

Label printing: For unmarked goods, the MES prints labels with all the necessary information (e.g. article number, batch number, production date).

Inventory Management

Storage rack allocation: The MES allocates the optimum storage rack for each item based on criteria such as item type, size, weight and stock availability.

Real time inventory management: The MES updates the stock level in real time as soon as the goods are put away. This ensures that the current stock is correctly displayed at all times.

ERP synchronization: All inventory data is synchronized with the ERP system to mark orders as complete and inform departments of goods flows.

Planning

ERP integration: Ensures seamless integration with ERP systems to ensure consistent data and uniform planning.

Detailed planning and scheduling: Enables the creation of detailed production plans, taking into account all resources and capacities.

Demand calculation: Determines the demand for materials and components and compares it with the current stock. Automated messages are sent in the event of shortages.

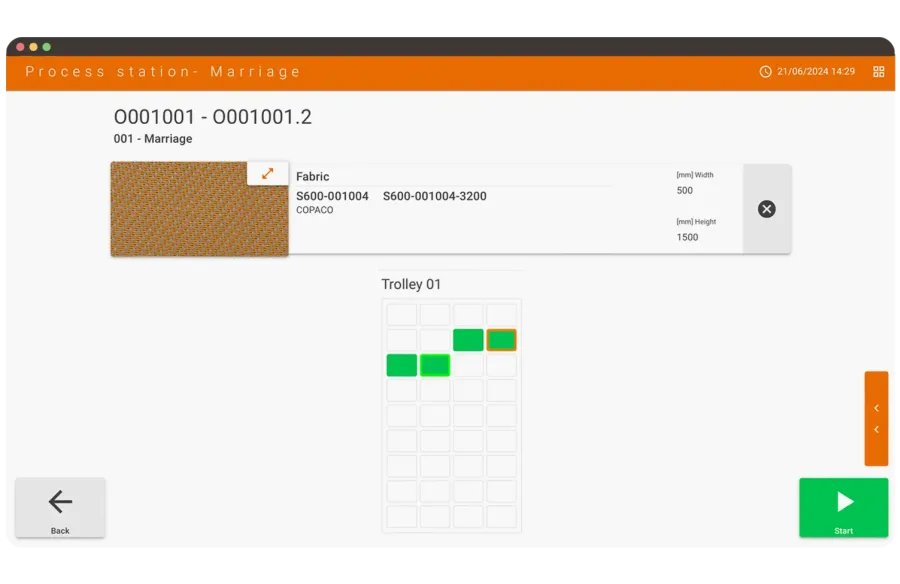

Production

Digital order paper: All necessary information for the individual process step can be called up digitally. Images, PDFs, videos and work instructions can also be integrated.

Order tracking: Tracks the progress of production orders in real time to view the status of each order at any time.

Shop floor communication: Supports direct communication between planning and production to pass on changes and instructions in real time.

Pick & Place by Light systems help users to keep track of their tasks at all times.

Analysis

Throughput times: Continuous tracking of production times means that all throughput times are collected, which in turn is used to plan orders.

Production reports: Generates detailed reports on production performance, capacity utilization and efficiency.

Traceability: The data generated is recorded down to the lowest level at all times and can be viewed years later.

High degree of customizability

With JAG NODE MES, you can customize your production data as you wish. Add new data points with just a few clicks or customize existing ones to display only the information you need at the station. Choose for each station how the data should be displayed to make it easier for users to keep track.

Intuitive design

Thanks to cross-industry standards and a consistent style, JAG-NODE's user interface is intuitive and easy to learn. Each user can customize the language and design to ensure an optimal user experience.

Scalability for every need

JAG-NODE was developed to scale from small to large manufacturing companies. The modular design allows you to choose what is most beneficial for your production.

Packed with functions

for smart production

Intelligence

Data and AI-supported waste optimization and consumption prediction.

Data acquisition

Production data acquisition (PDA) of machine data using modern interfaces as well as order data, quantities and unit numbers.

Dynamic adjustments

Dynamically adapts production plans and sequences to changes in the prioritization of orders or unexpected disruptions.

Dashboards

Displays key performance indicators (KPIs) and production data in clear dashboards.

Security

Protect important production data with state-of-the-art security functions and protocols.

Cloud

The NODE can optionally be purchased as a cloud service and is therefore quickly scalable, globally available and offers regular backups.