Laser

Tape Cutting

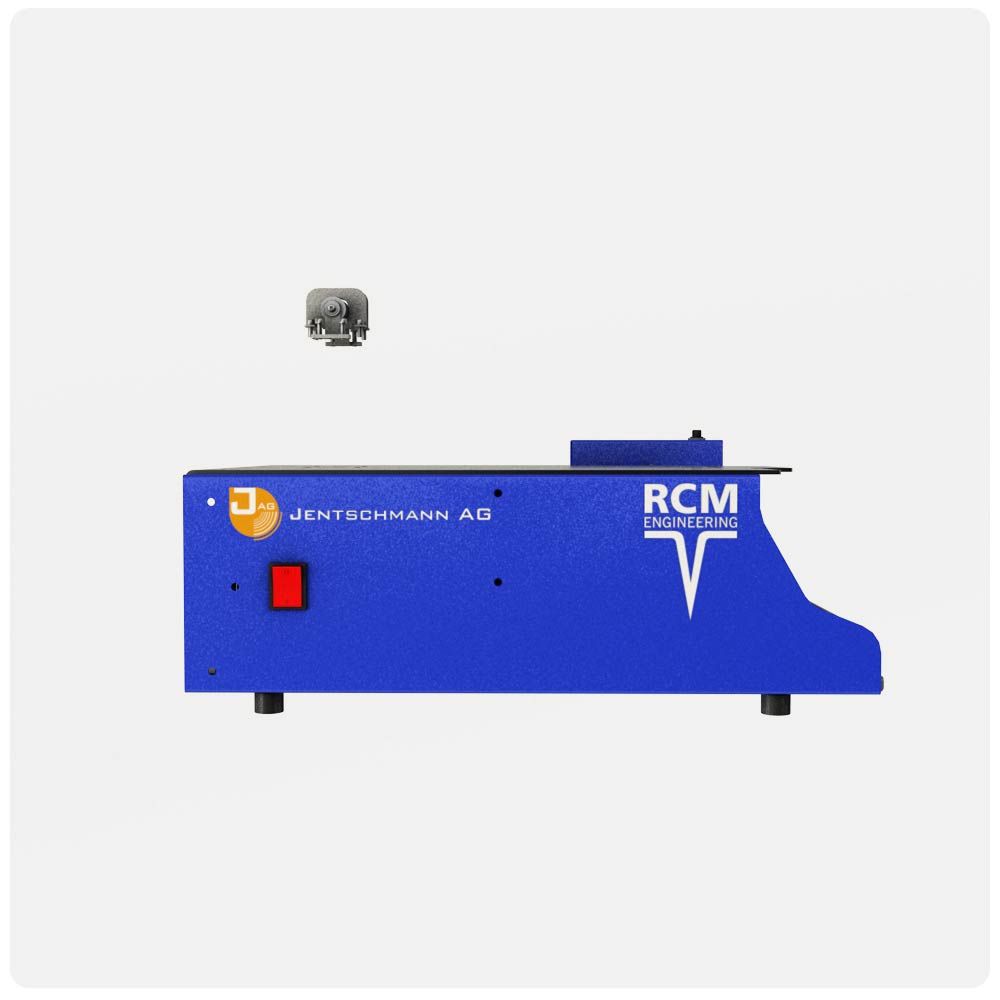

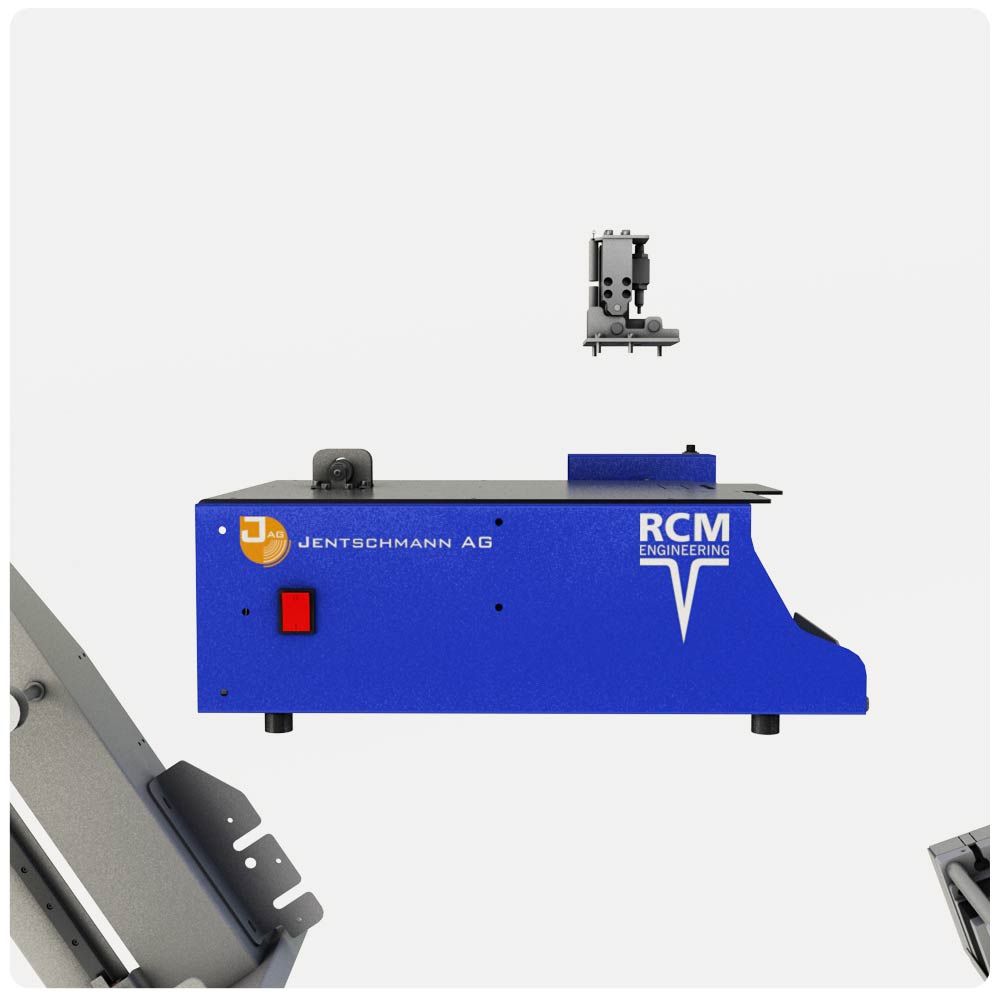

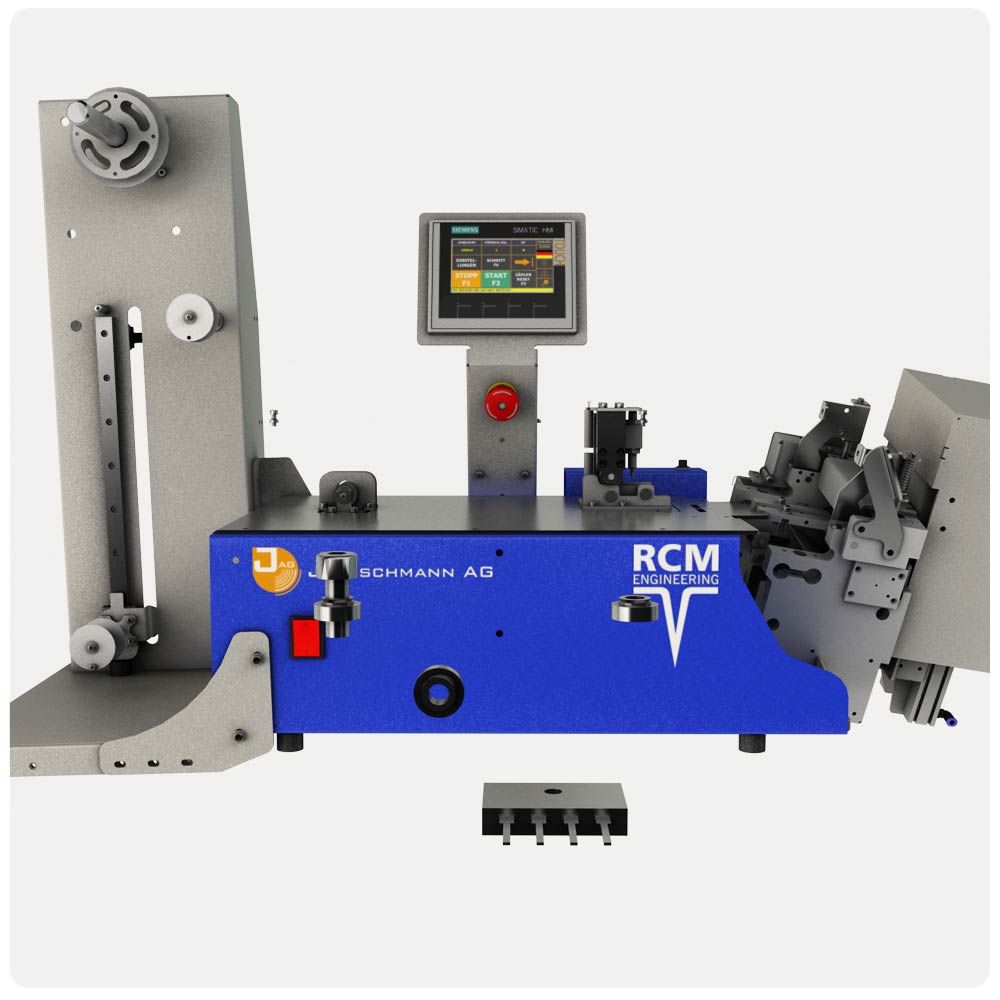

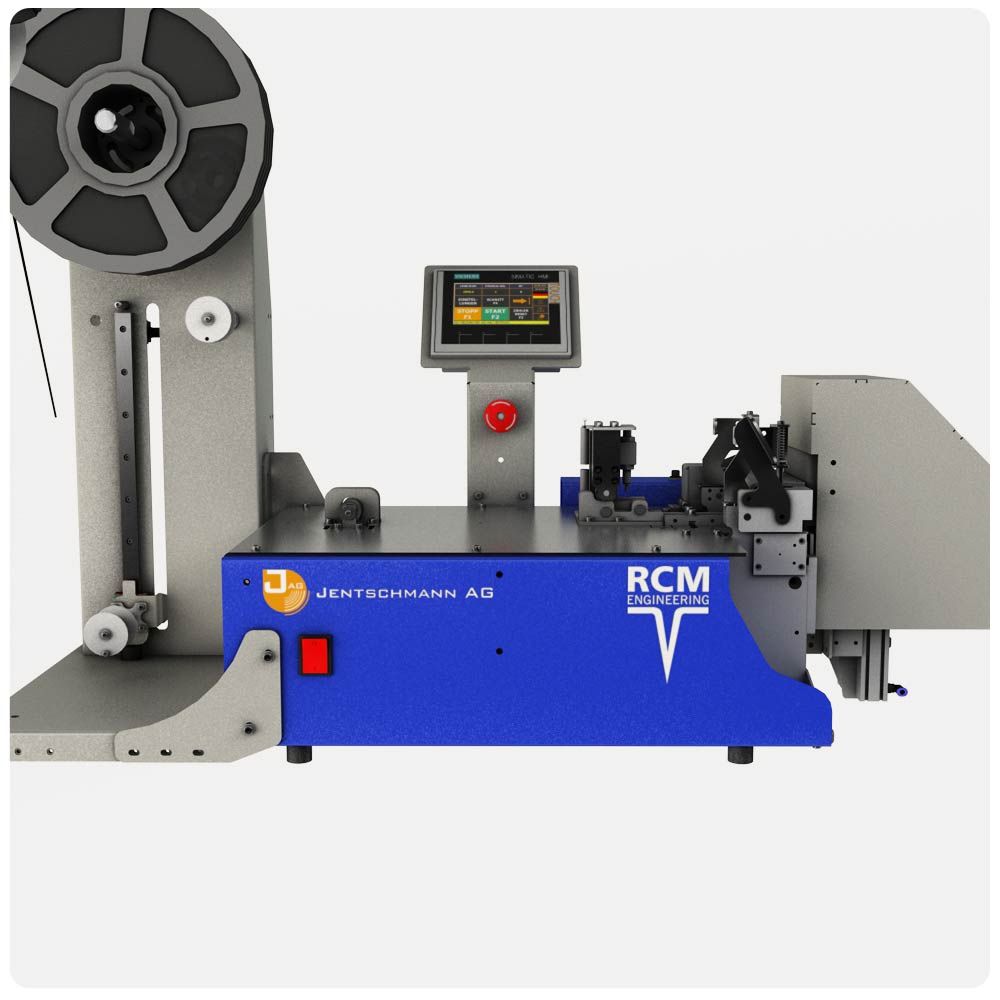

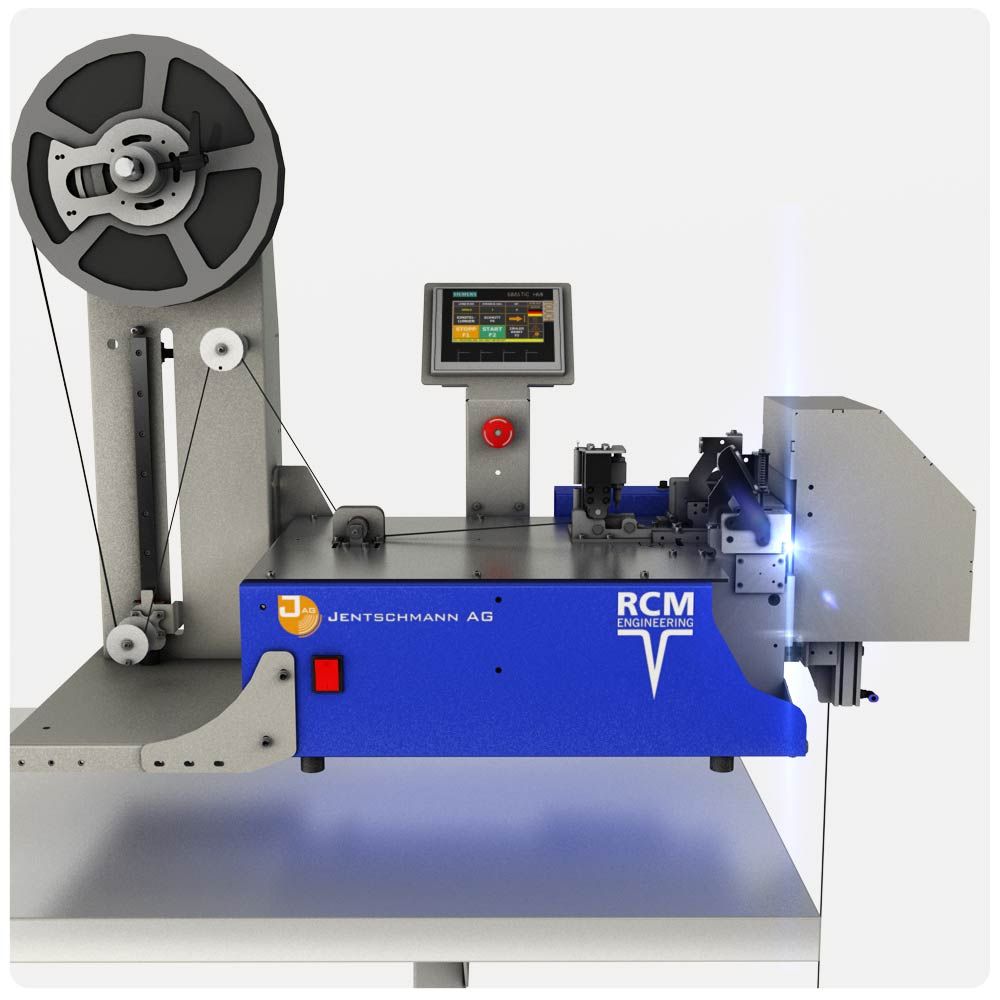

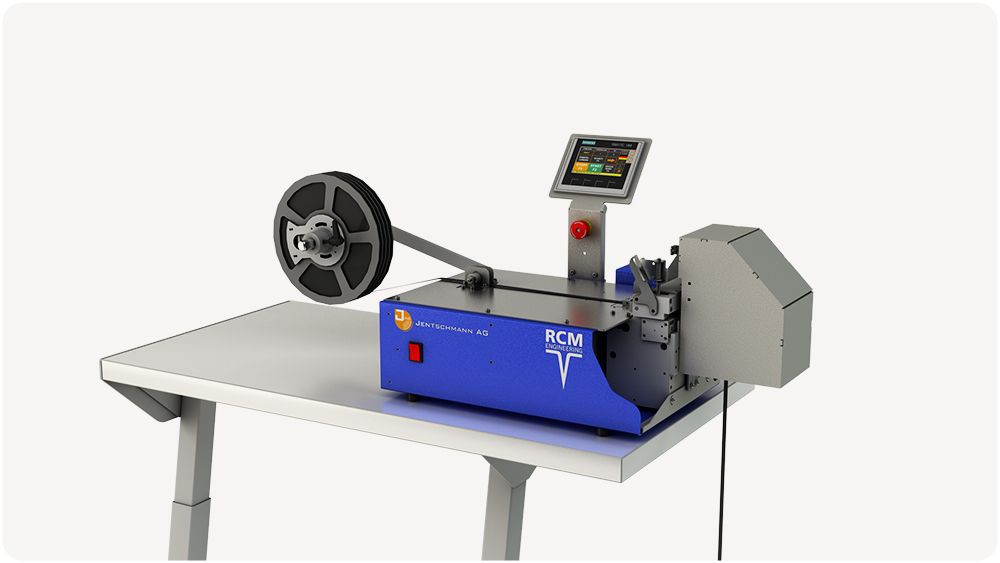

LaserCut PRO

RTC-208-TEX-85-L

New Technology

Suitable for any lifttape

LASER

CUT

LASER

CUT

Jentschmann AG and RCM are constantly working to develop more efficient machines.

The LaserCut Pro is the latest innovation in the field of lifttape cutting. High-quality components and years of experience also lead to exceptionally good results.

Let us give you an insight into the future-oriented way of cutting lifttape.

Cutting can be so beautiful

JULIUS KOCH WEBTEX

HUBER TEXBAND®

The LaserCut Pro was specially developed for processing Julius Koch's Webtex tape and Huber Bandfabrik's Texband®. This allows both tapes to be processed quickly and in consistently good quality on just one machine.

THE TECHNOLOGY BEHIND

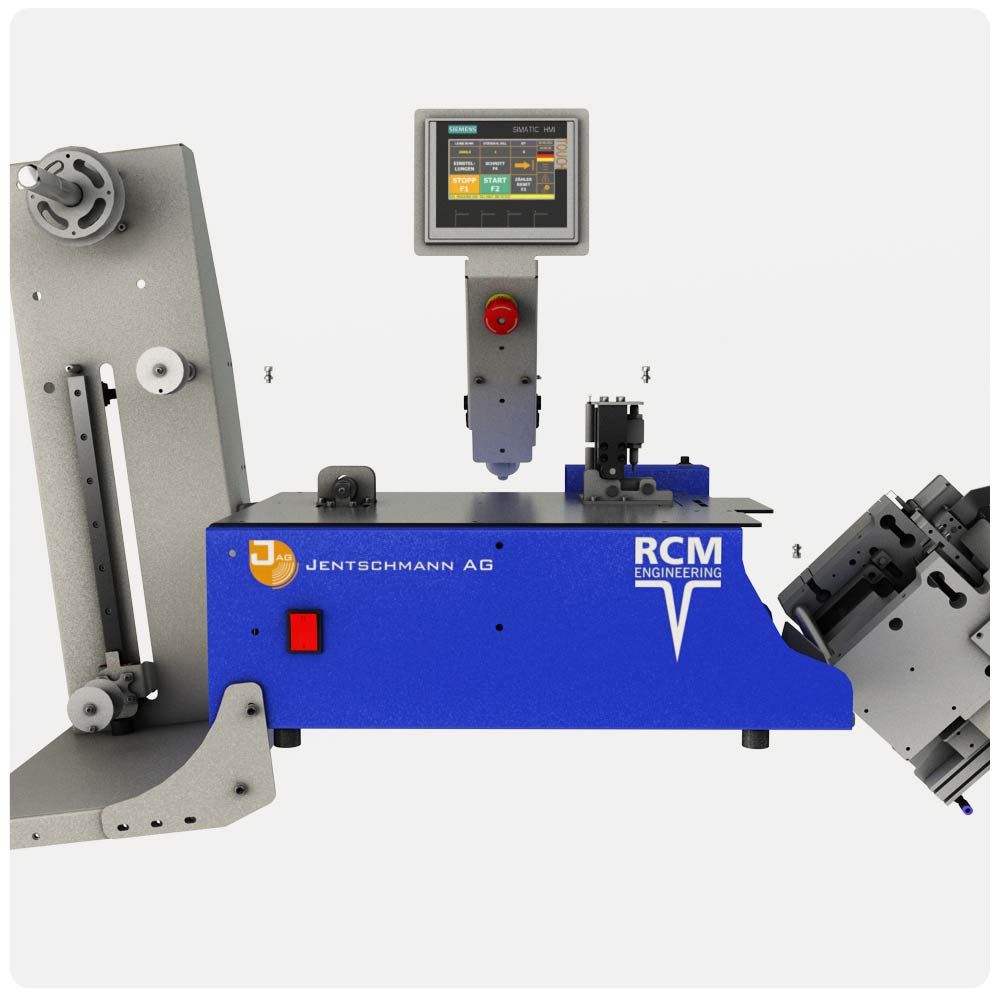

LASER CUT WITH RCM MARKING-SYSTEM

Due to the laser cut, the edges of the tape are sealed and are thus better protected against fraying. Both ends are marked with a fold embossing for the subsequent sewing process. This marking can be set between 15 and 30 mm from the end or beginning of the tape. Due to the light marking in the tape, the length accuracy from fold to fold can be maintained very precisely, even by less experienced personnel.

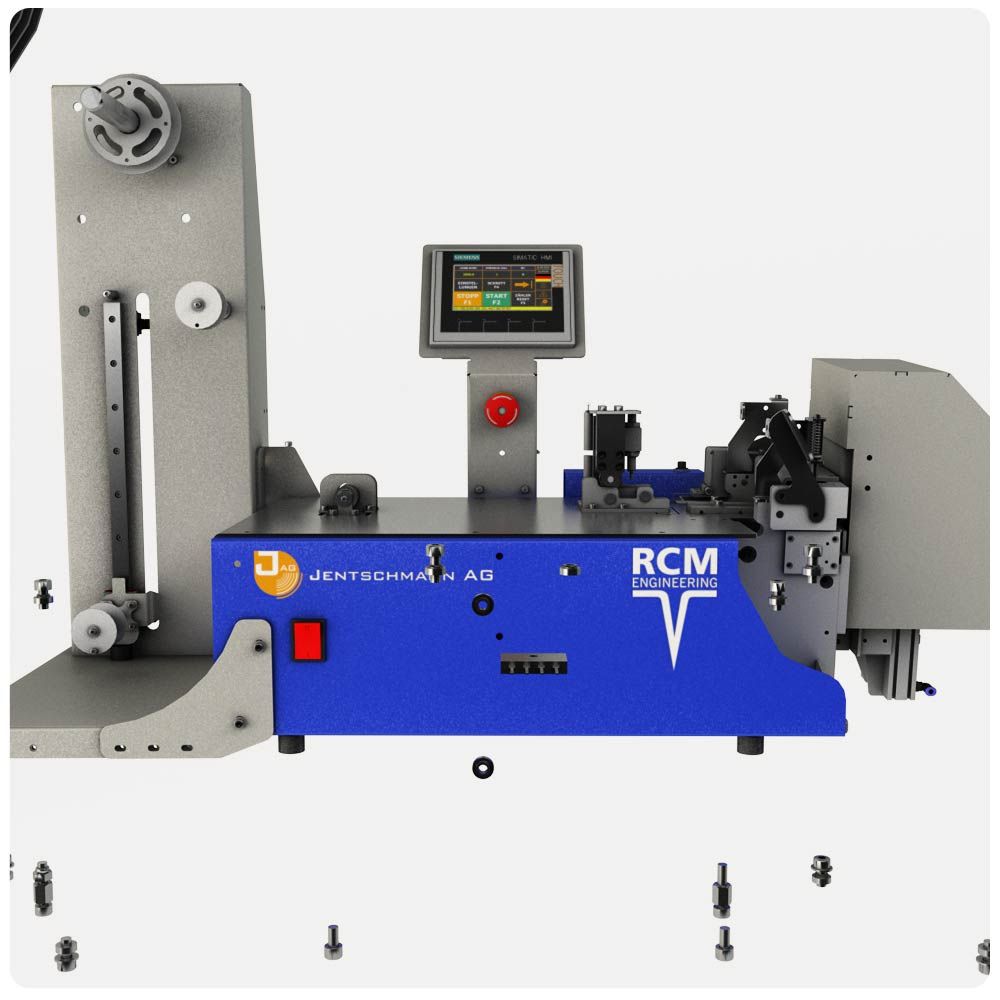

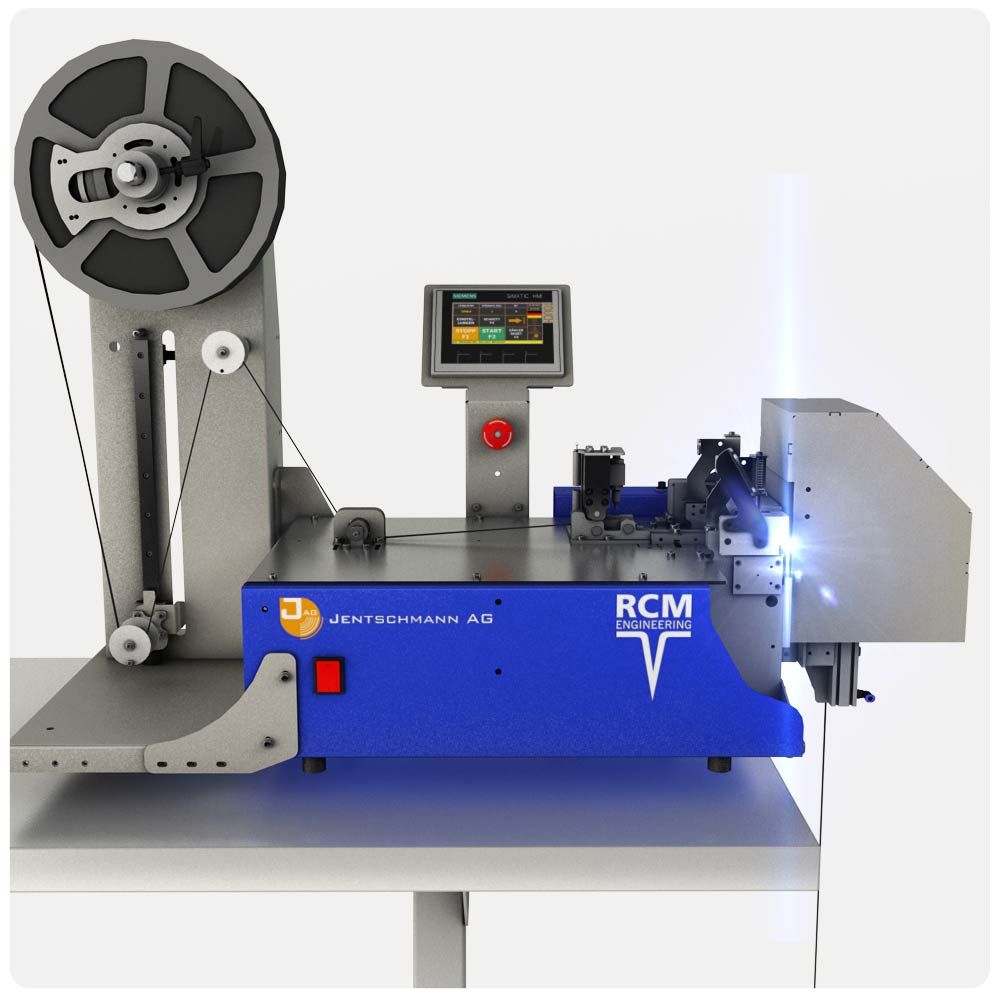

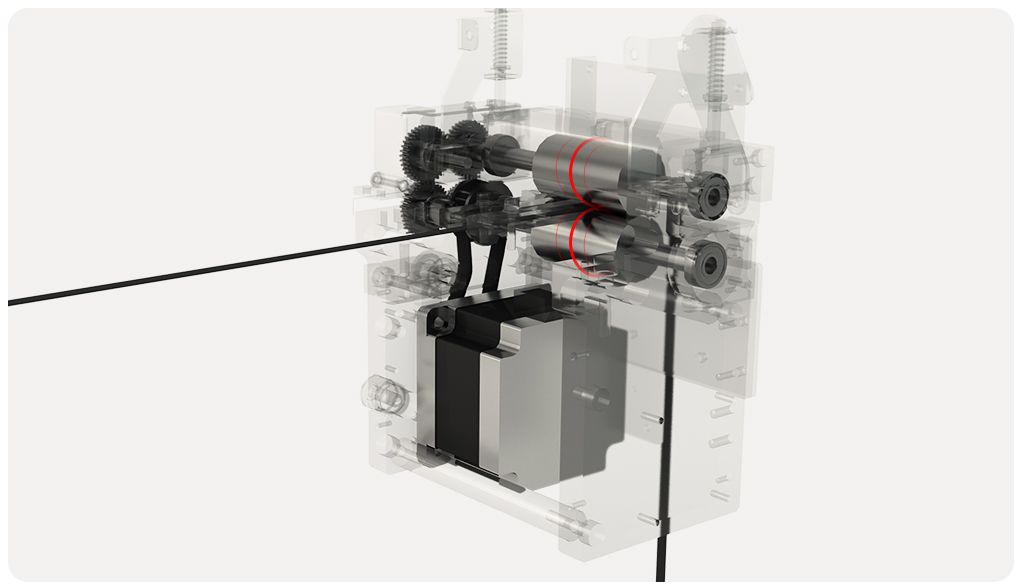

DOUBLE IS BETTER

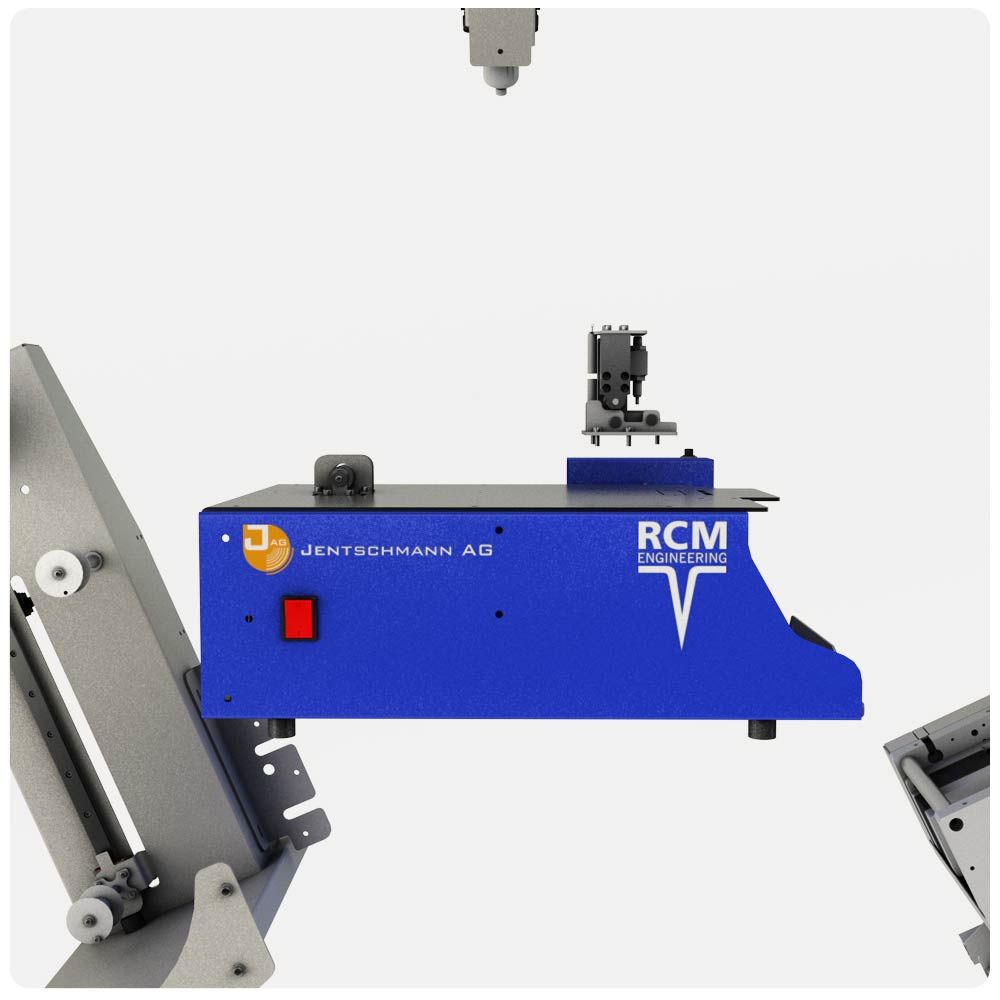

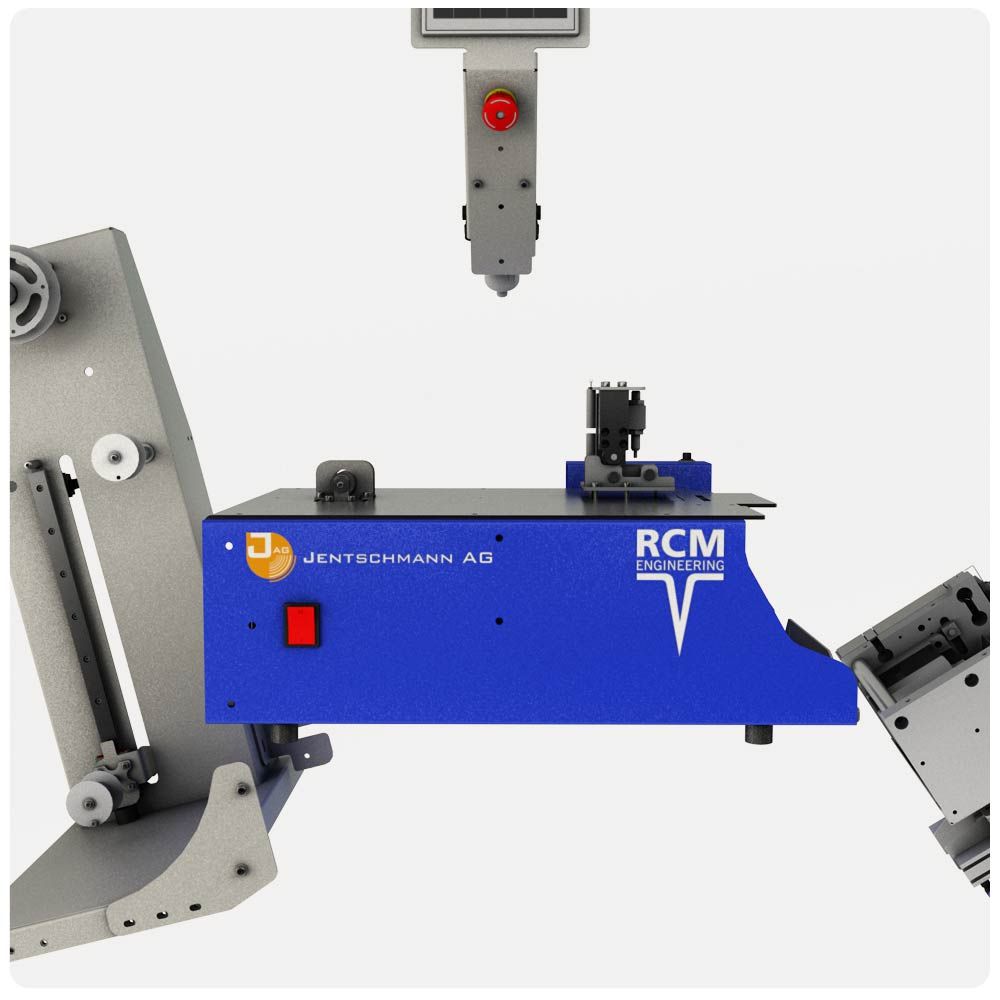

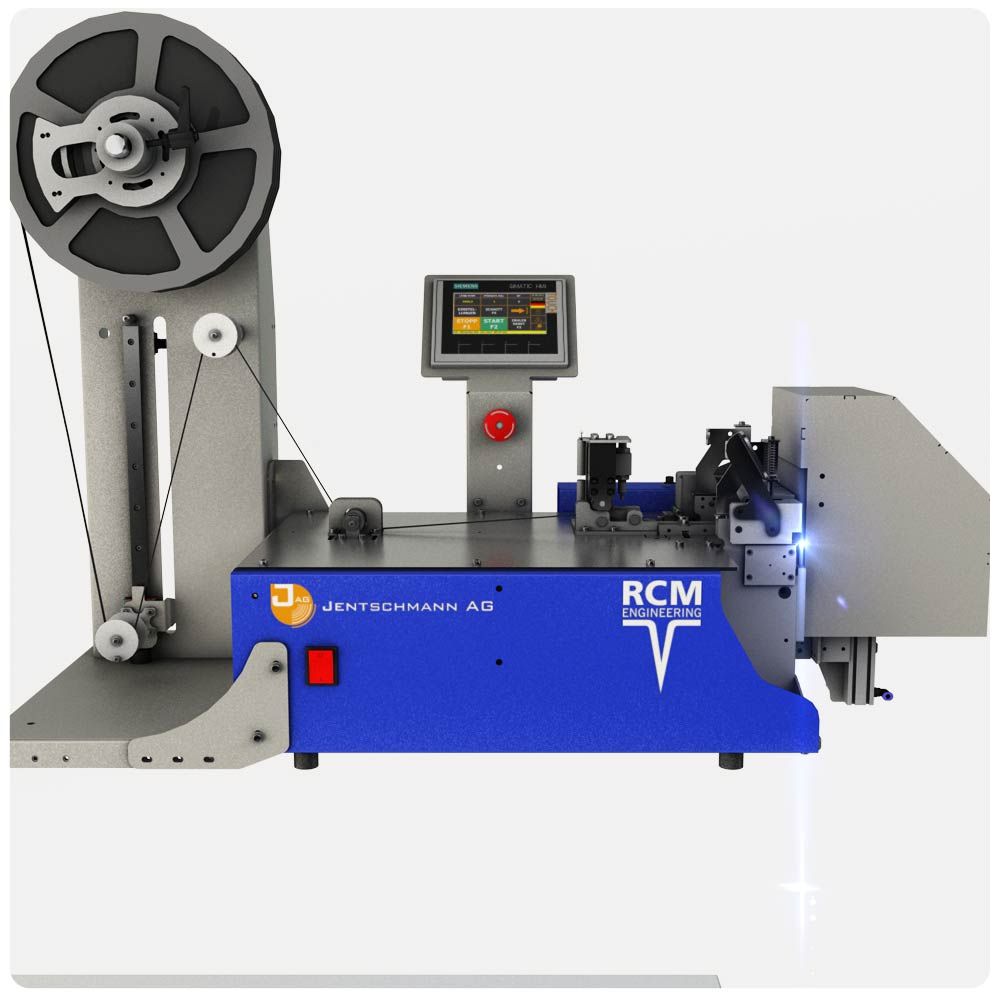

The tape is transported by two synchronously driven transport rollers (top and bottom) with double drive.

The film reel is driven by a motor when the tape is pulled off. The speed is controlled by a laser distance sensor. The roller dancer with sensor control ensures tension-free tape take-off.

Because of that, the working speed of the machine is very high. It can cut up to 350 tapes that have a lenght of 2 m within one hour.

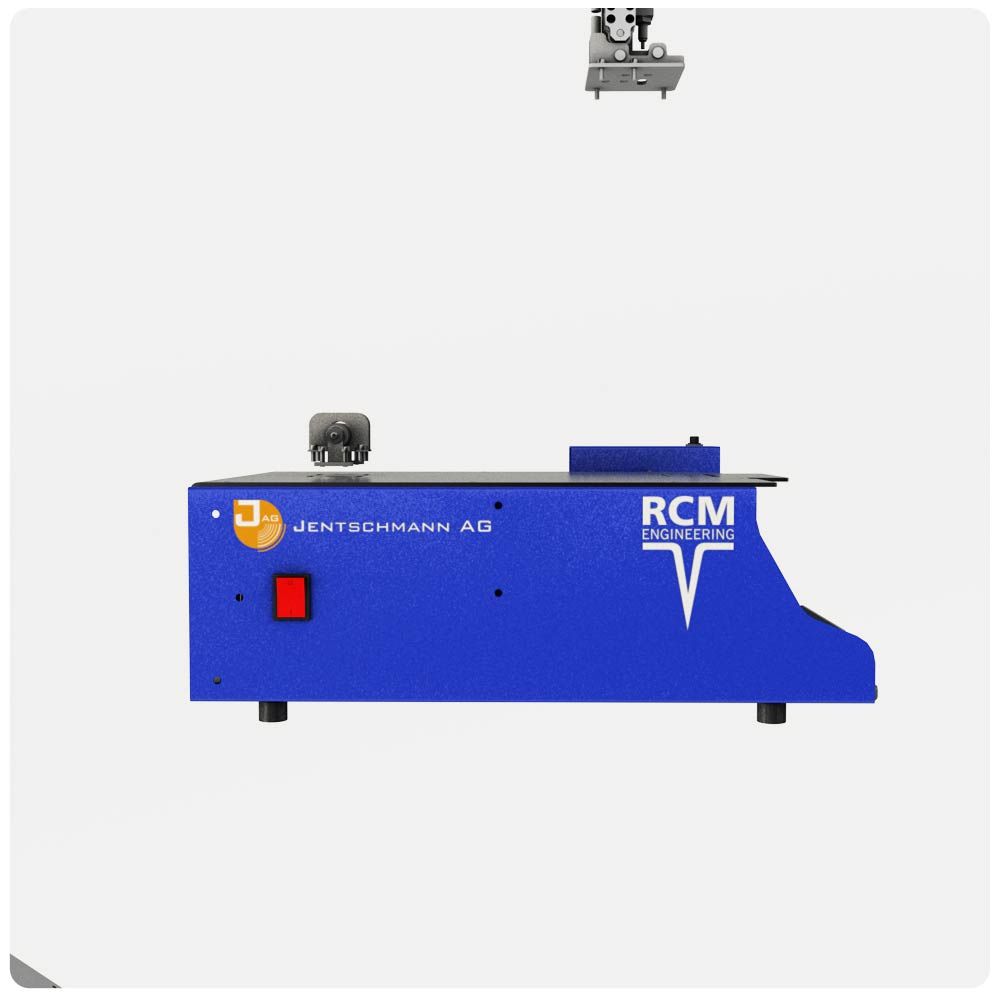

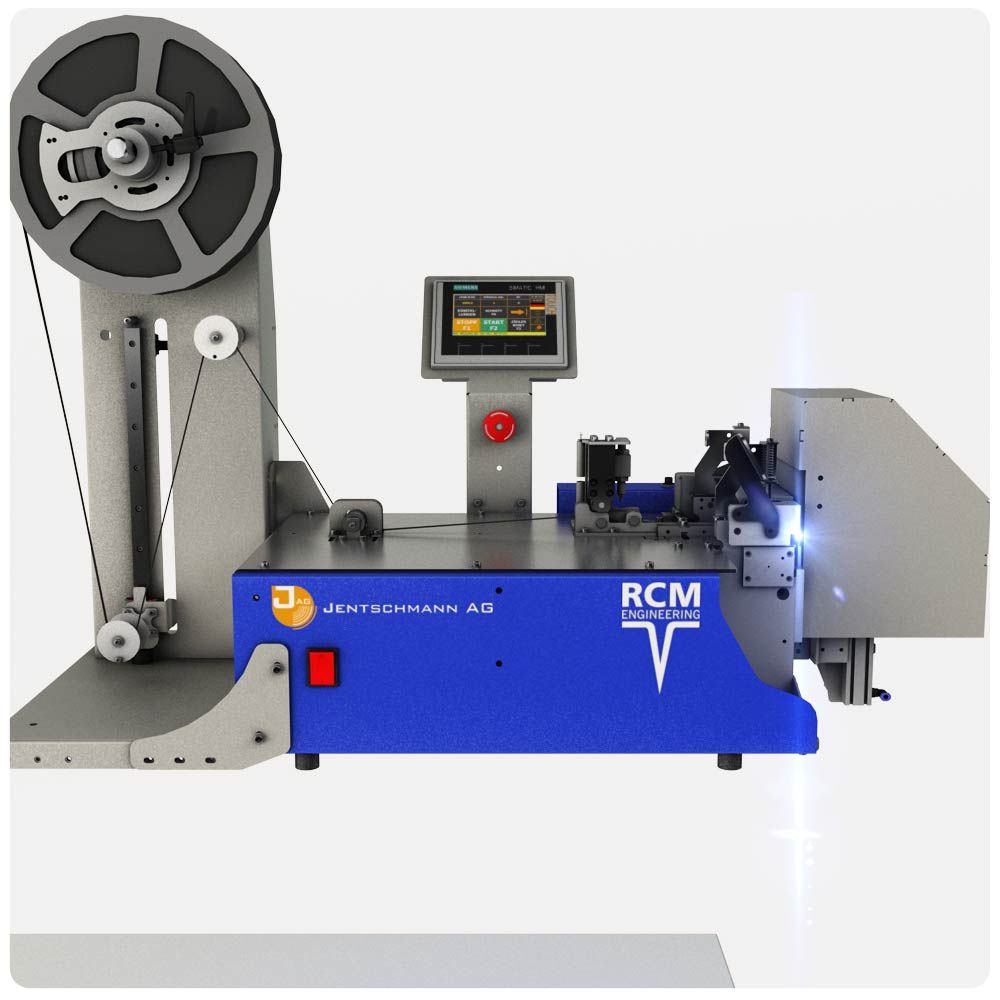

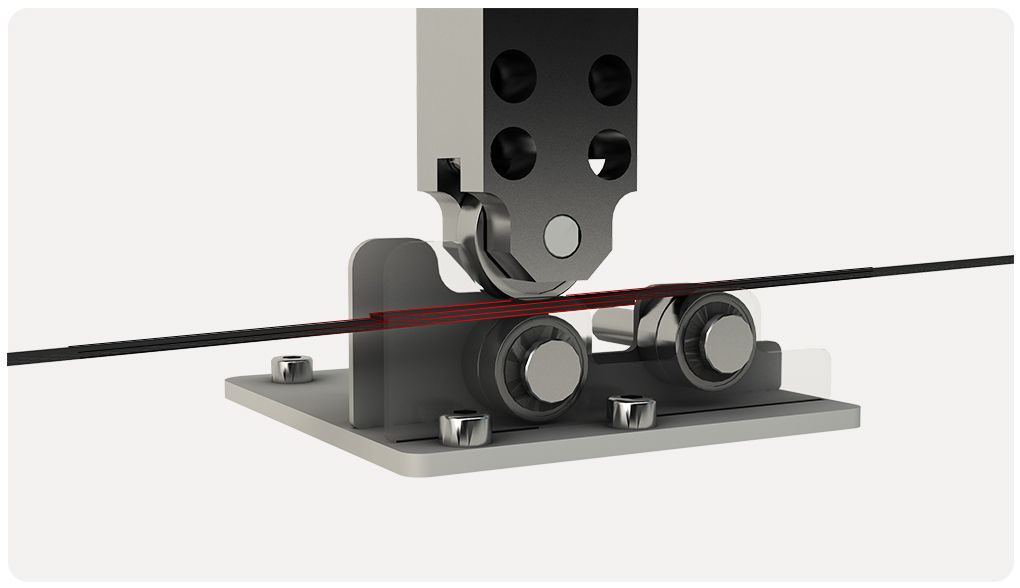

TAPE THICKNESS CONTROL

During transport, the tape is checked for thickness differences (accuracy 0.01 mm) via a special sensor, so that no tapes with a seam connection can enter further processing.

As soon as this thickened area is detected (e.g. by a sewn-together tape), the LaserCut stops the tape transport.

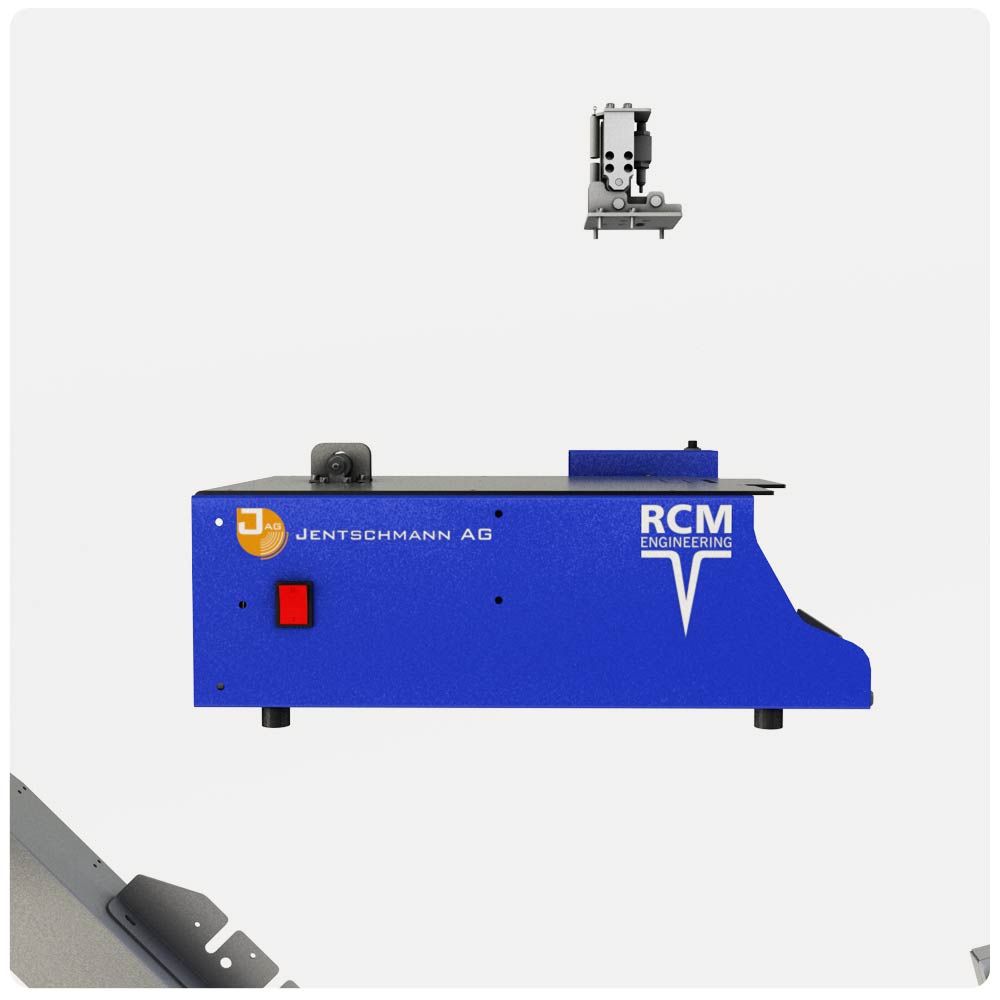

EASY HANDLING

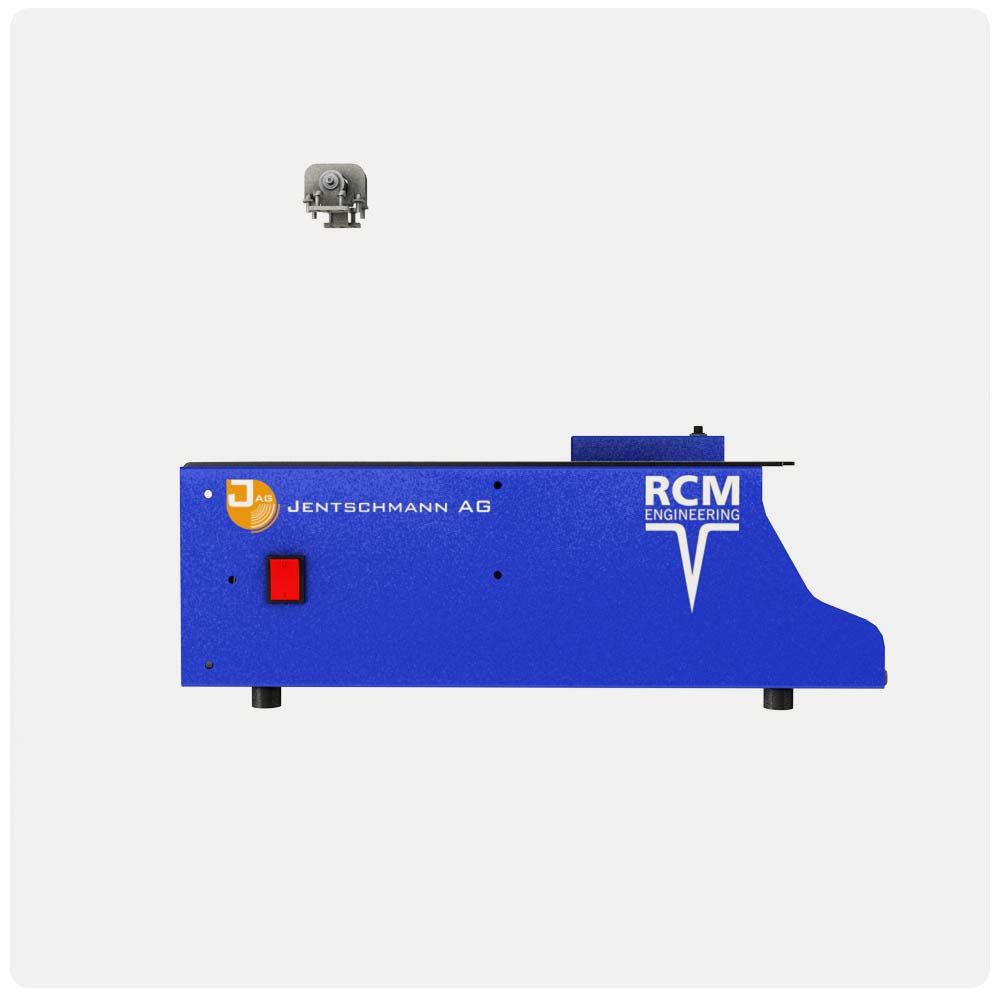

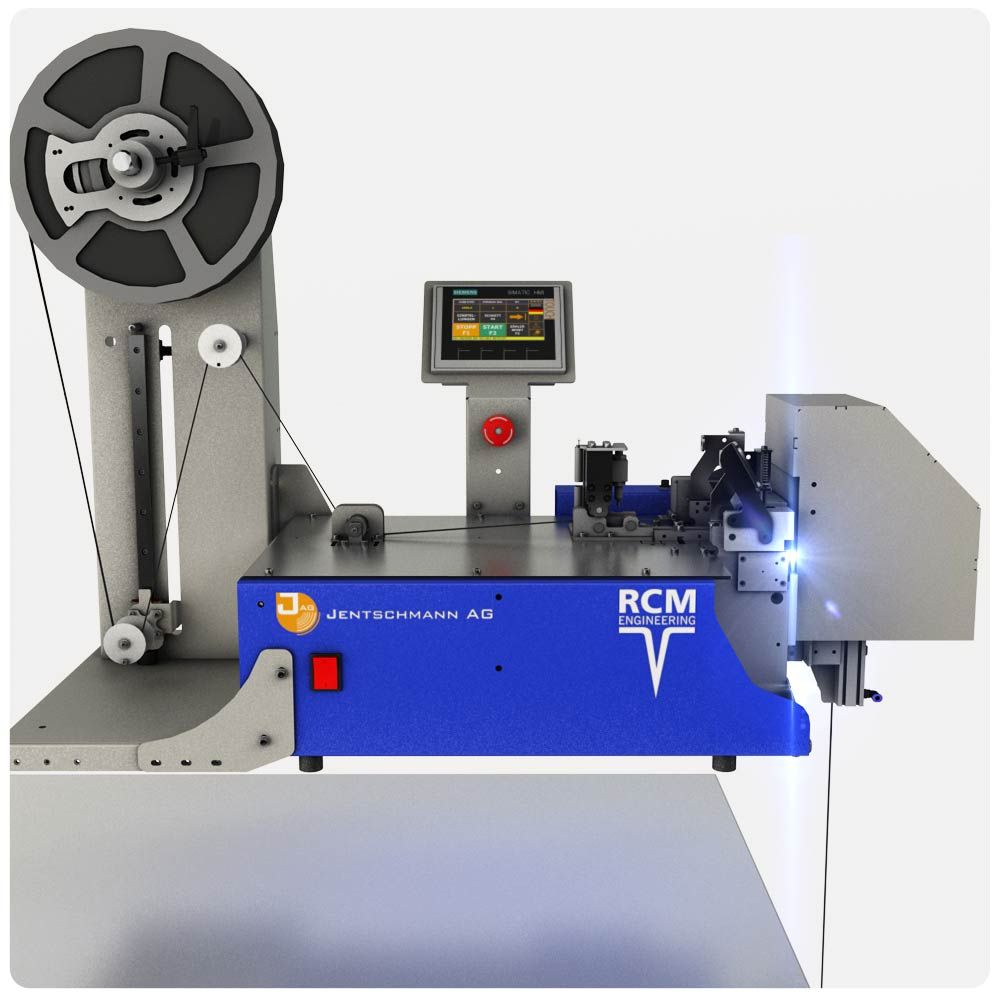

To prevent the cut lift tapes from falling to the floor, a stacker is attached. Up to 30 pieces can be clamped in the stacker and released with a push of a button.

That is why the LaserCut

is the right solution for you

- Processing of both Webtex (Julius Koch) and TEXBAND® (Huber Bandfabrik) possible.

- Laser cut for sealed edges - no fraying.

- RCM marking system - fold marking for easy recognition of the fold point.

- Stacker for clamping the already cut tapes.

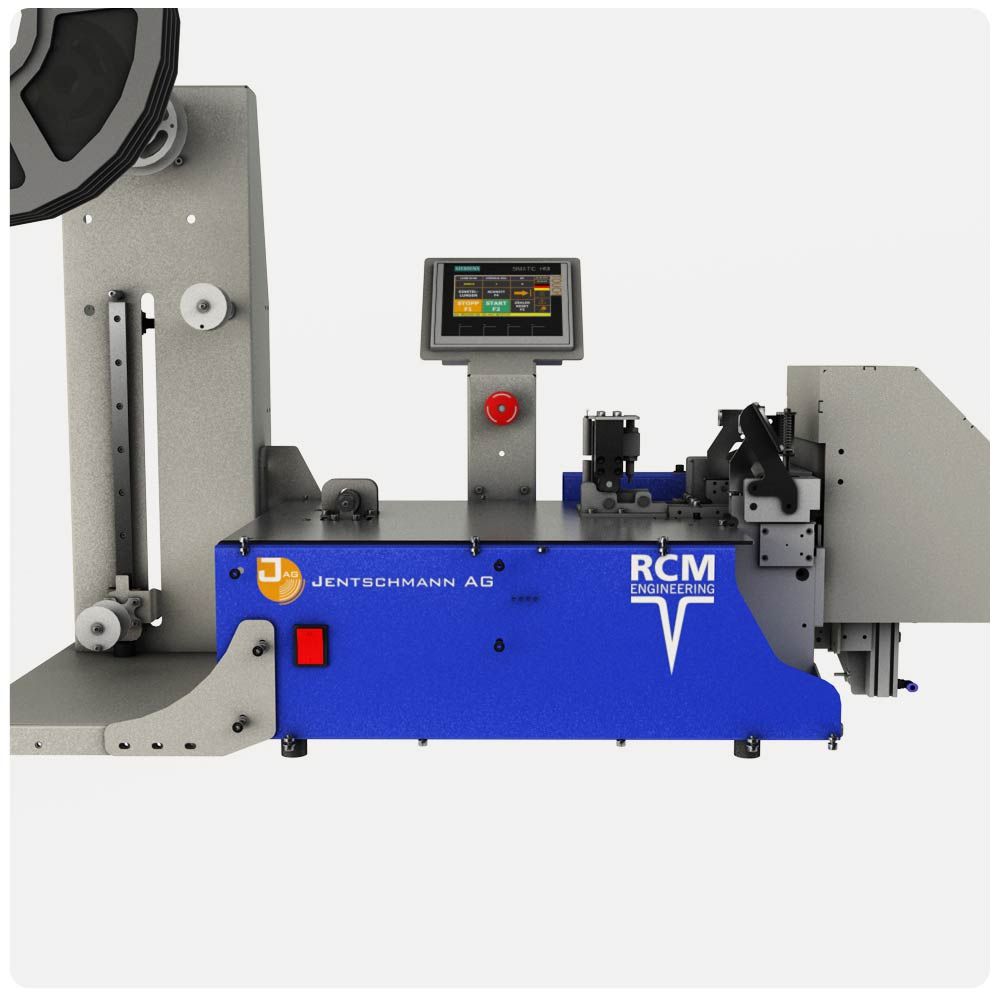

- Tape take-off via driven film spool with dancer control.

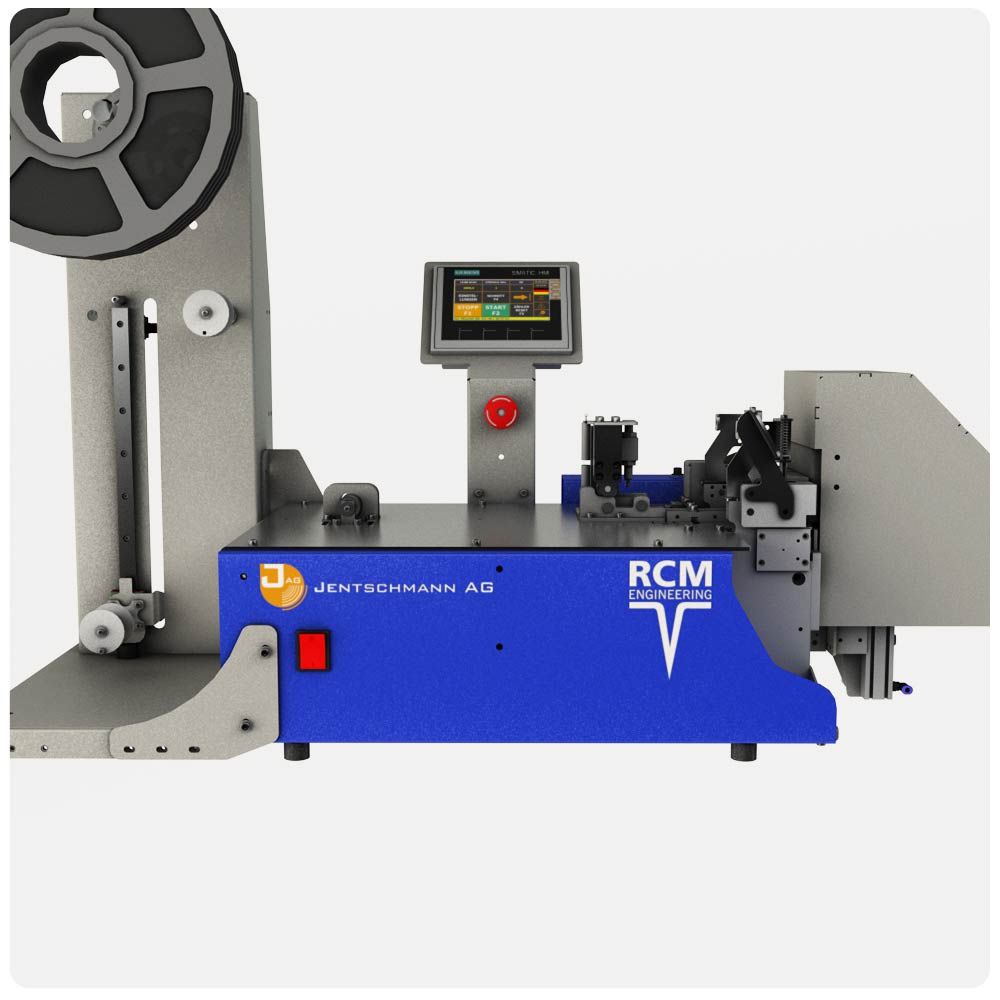

- Tape feed speeds up to 30 metres per minute.

- Integrated tape error control system.

- Tapes with 6, 8 and 10 mm width can be processed.

- Length and quantity can be set on the display or entered via barcode scanner/network.

- Label printer for printing the desired order data.

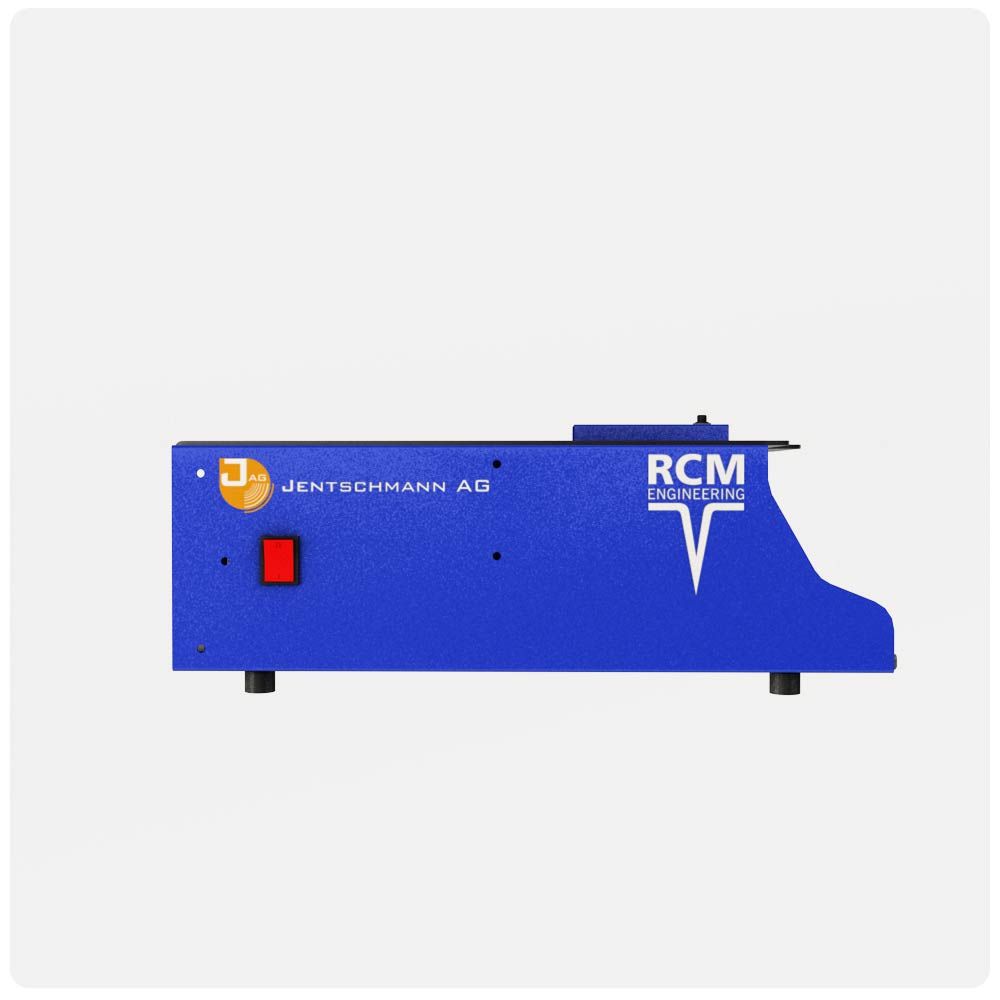

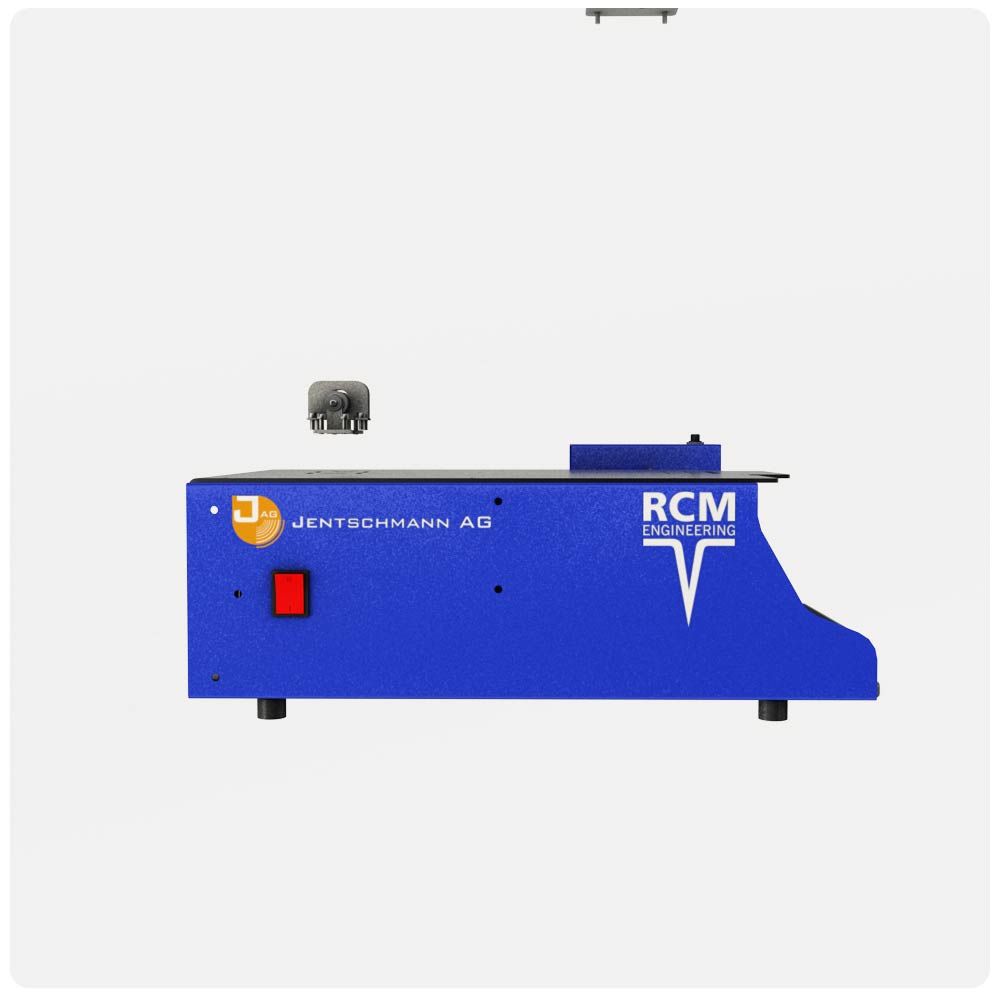

- Low space requirement.

- Simple and intuitive handling.

- High-quality components and workmanship of the machine.

- Fast and very good quality output of the cut tapes.

Variants

The LaserCut is available in two different versions.

LaserCut Eco

The LaserCut Eco is the basic machine and is suitable for small and medium production lines.

The basic equipment includes:

- RCM marking system

- Laser cutting for sealed edges

- Driven transport roller at the bottom

- Rigid film spool holder

- Length and quantity freely adjustable

LaserCut Pro

The LaserCut Pro is the fully equipped machine and is suitable for larger production outputs.

In addition to the basic equipment, the following additional features belong to the LaserCut Pro:

- Roller dancer with sensor control for tension-free tape removal

- Speed control with laser distance sensor

- Driven film spool shaft

- Tape error control system

- Stacker for clamping the already cut tapes

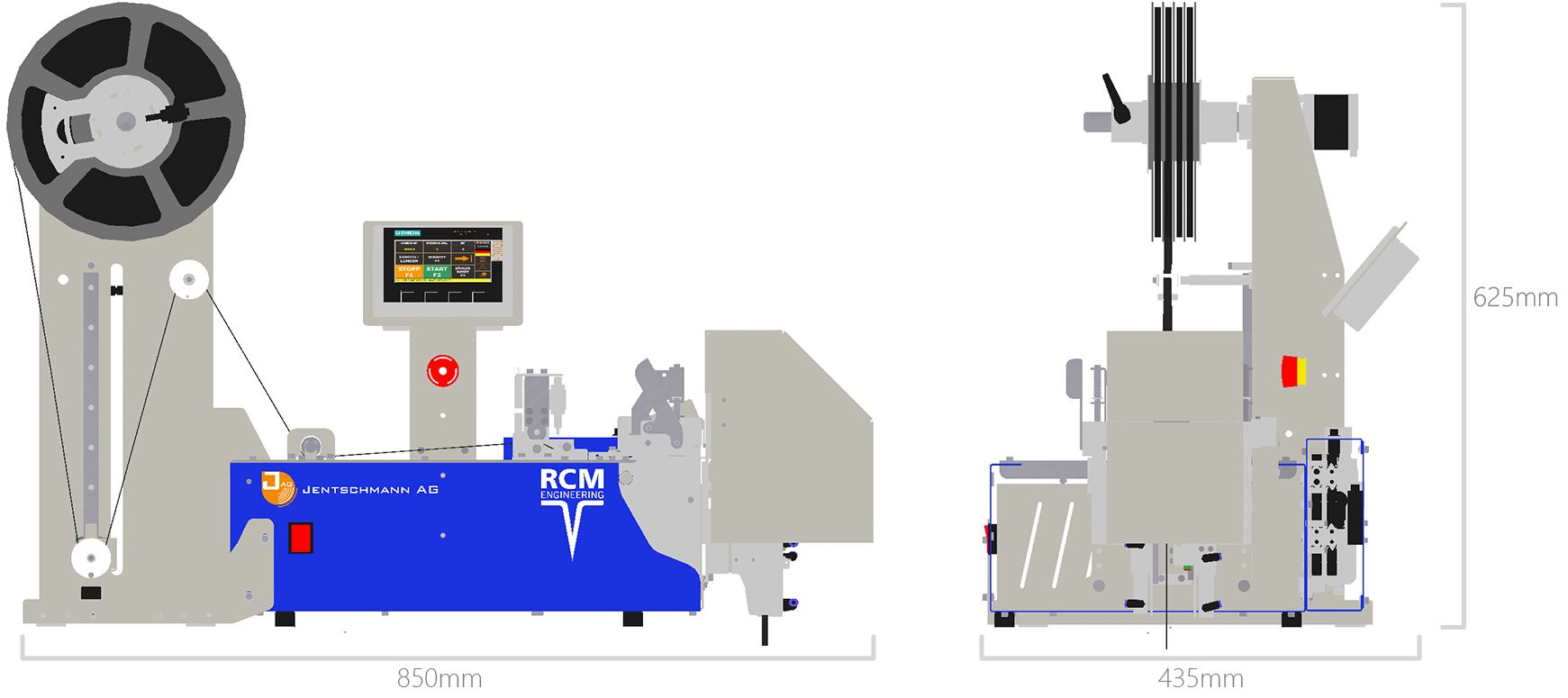

Technical details

The data may vary depending on the version.

-

Working speed

up to 350 pcs. à 2m per hour

-

Processable fabric types

Webtex of Julius Koch

TEXBAND® of Huber Bandfabrik -

Connections

Electric: 230V / 60Hz

Pneumatic: stable 6 bar, dry, oil-free, 100l/min (Class 0) -

Dimensions and weight

Height: 625mm

Length: 850mm

Width: 435mm

Weight: ca. 30 kg