ACRYL

CUT

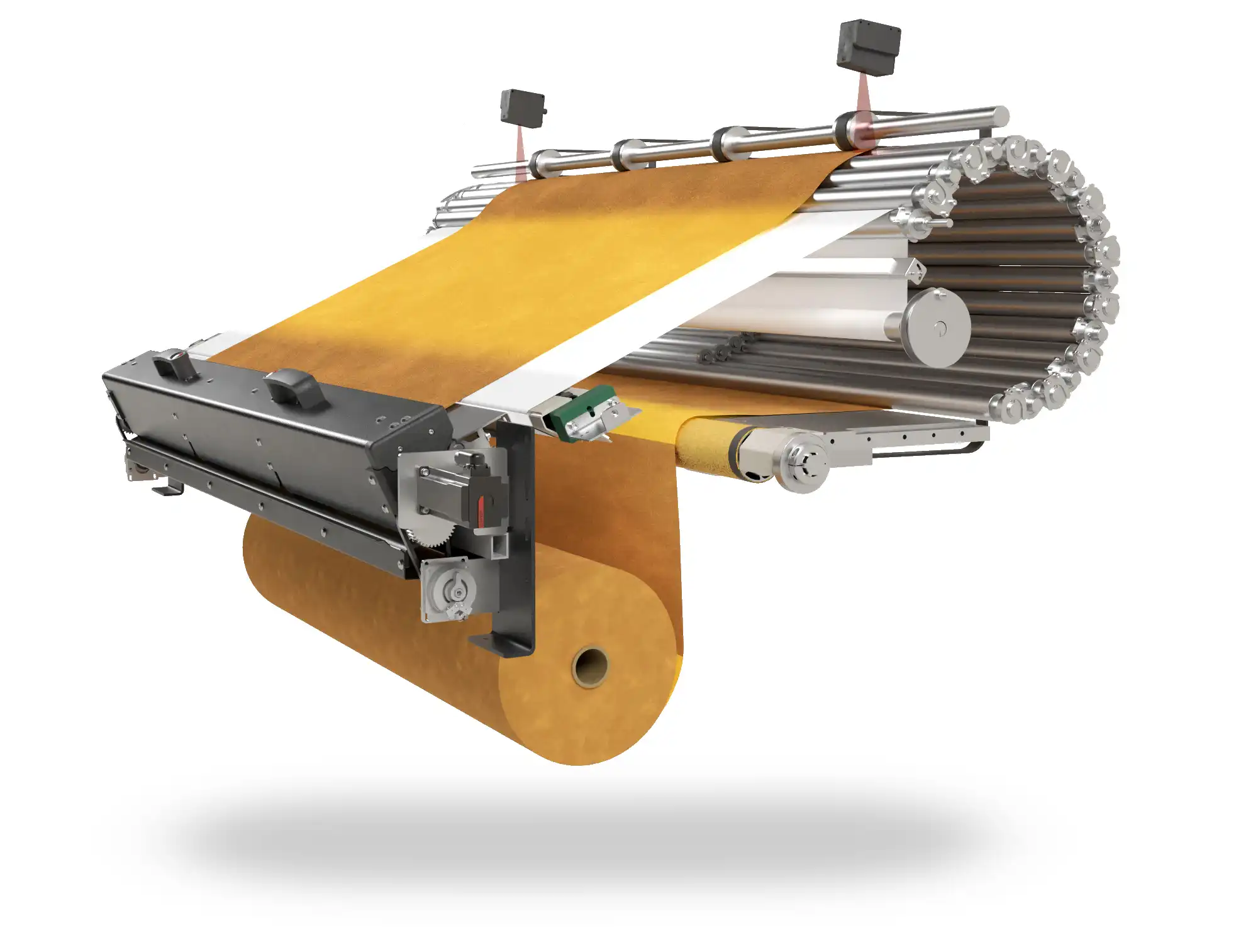

The AcrylCut is a highly dynamic cutting machine for fabrics with a width of 1.2 metres. The revolutionary design of the machine achieves significantly higher productivity in the smallest of spaces. The machine works almost fully automatically.

The "from-roll-to-roll" working method allows the highest measured productivity in awning production with a very small footprint of just 2.9m².

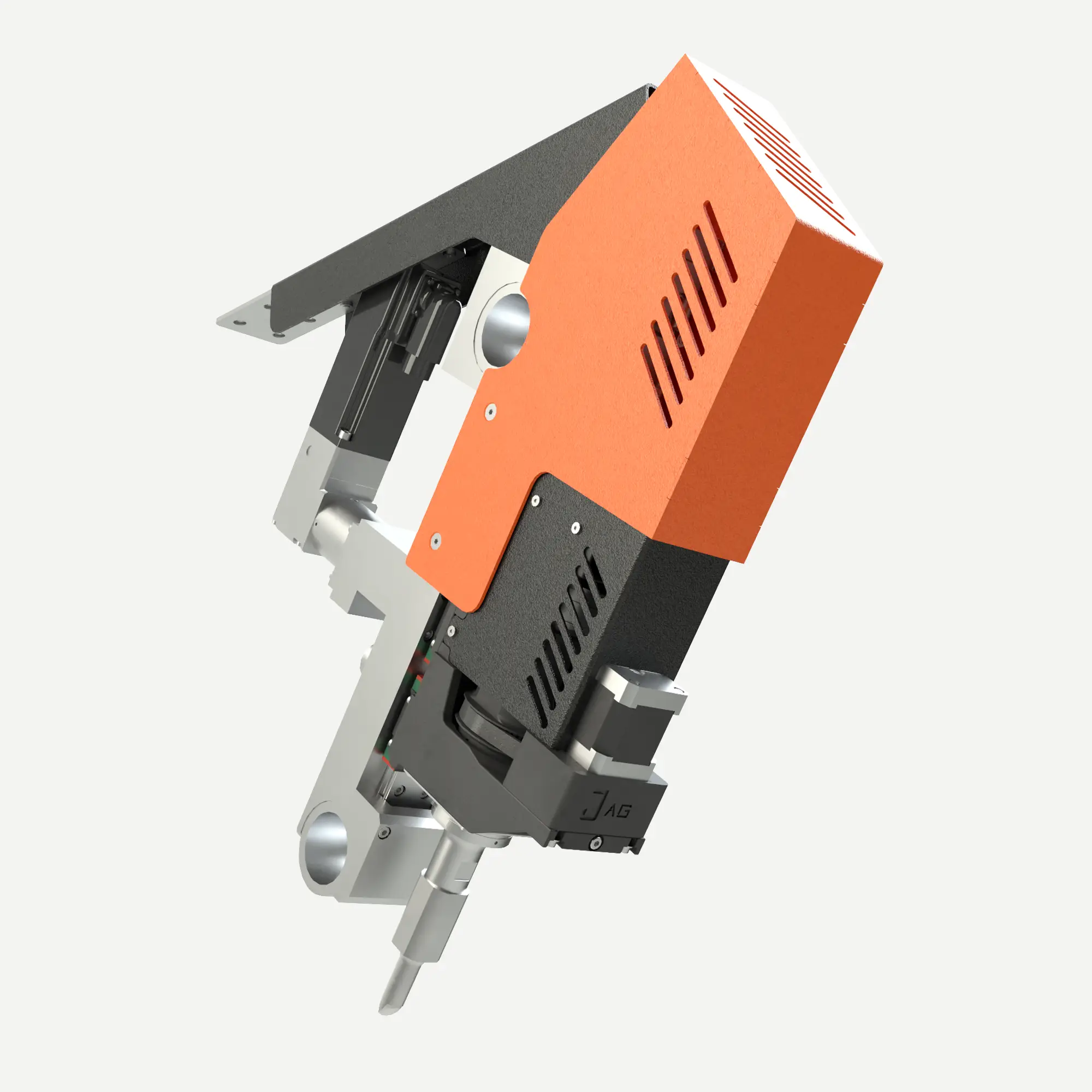

CUTTING HEADS

With maximum flexibility.

BEST TECHNOLOGY IN THE SMALLEST SPACE

The cutting heads have an ultrasonic cutting sonotrode to cut typical fabrics from the textile external sun shading industry, such as acrylic and polyester, and seal the edges at the same time.

THREE AXES PER CUTTING HEAD

Each cutting head has three axes:

Positioning axis

Cutting axis

Rotation axis

This allows the textile to be cut with millimetre precision and with a programmable cutting pressure in the longitudinal and transverse directions.

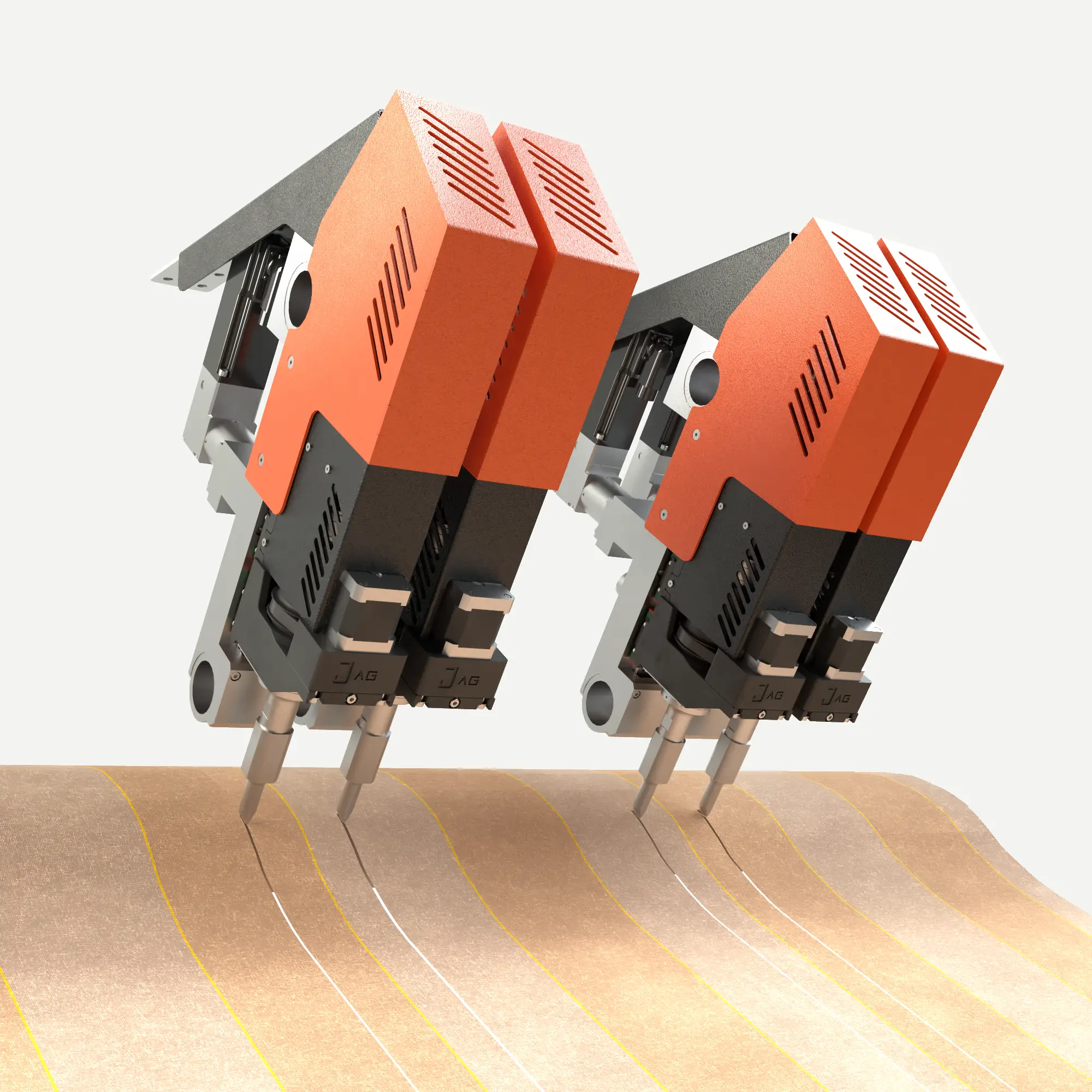

UP TO 4 CUTTING HEADS

By using several cutting heads, an optimum waste ratio can be achieved, for example one or more reinforcement strips can be cut out with repeat accuracy.

NO OTHER MACHINE IS THIS FAST

1.6 x faster than conventional table cutting

Cutting cycle of only 25 seconds including handling of the fabric.

From "start" to "start".

VARIANTS

The AcrylCut is available in various configurations.

AcrylCut Solo

With the AcrylCut Solo version, the fabric roll is placed manually from the front into the unwinding tray in the machine. A fabric trolley next to the machine collects the individual cuts and is then moved to the next processing machine. Approx. 10 x orders with a standard size fit into the fabric trolley. (5 x panels per order)

AcrylCut MHS

The step towards "paperless production".

The AcrylCut can also be connected to the "Material Handling System MHS". Here, the individual cuts are assigned to defined storage compartments of the fabric trolleys by means of a "Pick-By-Light" function.

AcrylCut RLS + MHS

The AcrylCut RLS version works with an automatic fabric roll changer at the rear of the machine. The fabric roll changer has two stations - one station for returning the roll and one waiting station for the next roll.

This minimises waiting times, as the next roll can already be loaded into the waiting station next the AcrylCut machine.

The AcrylCut can work independently from the RLS. Loading new rolls in the storage system or preparing the next roll has no influence on the cutting process of the AcrylCut anymore.

TECHNICAL DATA

The data may vary depending on the version.

-

Operating Area

Max. cutting width: 1.300mm

Max. cutting length: not limited (depending on material and material weight) -

Fabric Roll

Fabric widths: 430mm - 1.250mm

Max. roll diameter: 280mm -

Fabric types

Acrylic, polyester and similar textiles for awning production

-

Dimensions and weight

Height: 1.780mm

Width: 2.190mm

Depth: 1.330mm

Weight: app. 1.500kg (depending on equipment)

-

Connection

Electrical power: 400V / 50Hz, 3 phases, 16A

Pneumatics: Ø 8mm, stable 8bar, dry, oil-free (class 0)

Network: Ethernet (100/1000 Mbit)