DIGITAL PAPERLESS PRODUCTION

MATERIAL HANDLING SYSTEM

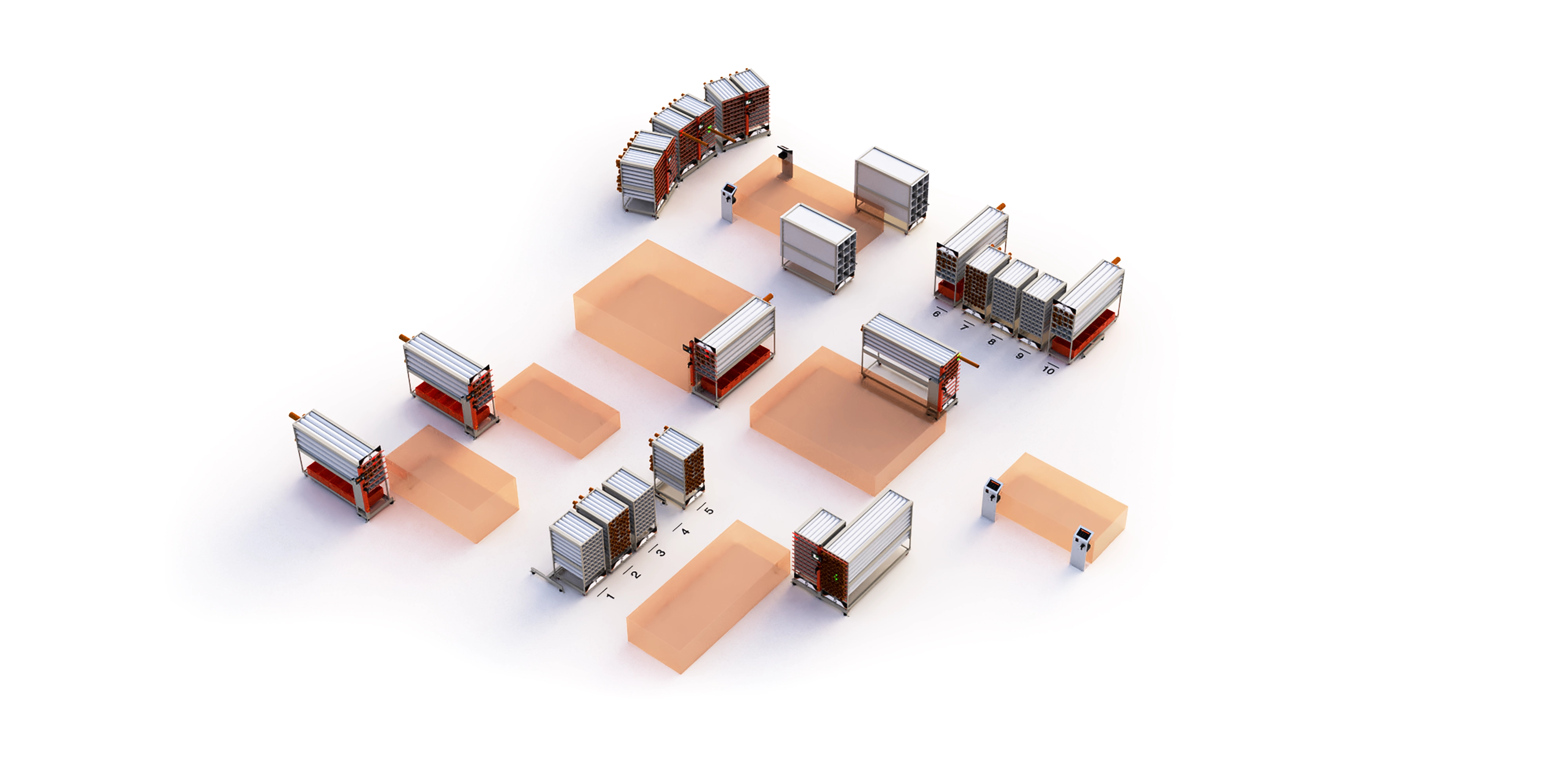

The Material-Handling-System is used to digitize production and consists of several components that communicate with the higher-level MES system NODE.

THE NETWORKING OF PRODUCTION

SCAN

Connect all production steps with our MHS and benefit from 100% order traceability.

THE BUILDING BLOCKS FOR YOUR DIGITALIZATION

MHS LOADING STATION

In most cases, the workflow of an order starts at the cutting station. Communication between the MHS station and the cutting machine is used to distribute and assign the relevant cuts to the trolleys.

MHS HUB

In the MHS HUB, each trolley has a defined parking position to buffer the orders between cutting and the processing machine. This means that orders can be found quickly and easily by staff.

MHS UNLOADING STATION

Each subsequent process after cutting receives an MHS retrieval station, which provides the order information digitally and displays the position in the trolley. A traffic light system informs the operator which orders need to be processed urgently.

PAPERLESS PRODUCTION

Processes and workflows can be digitized with the MHS.

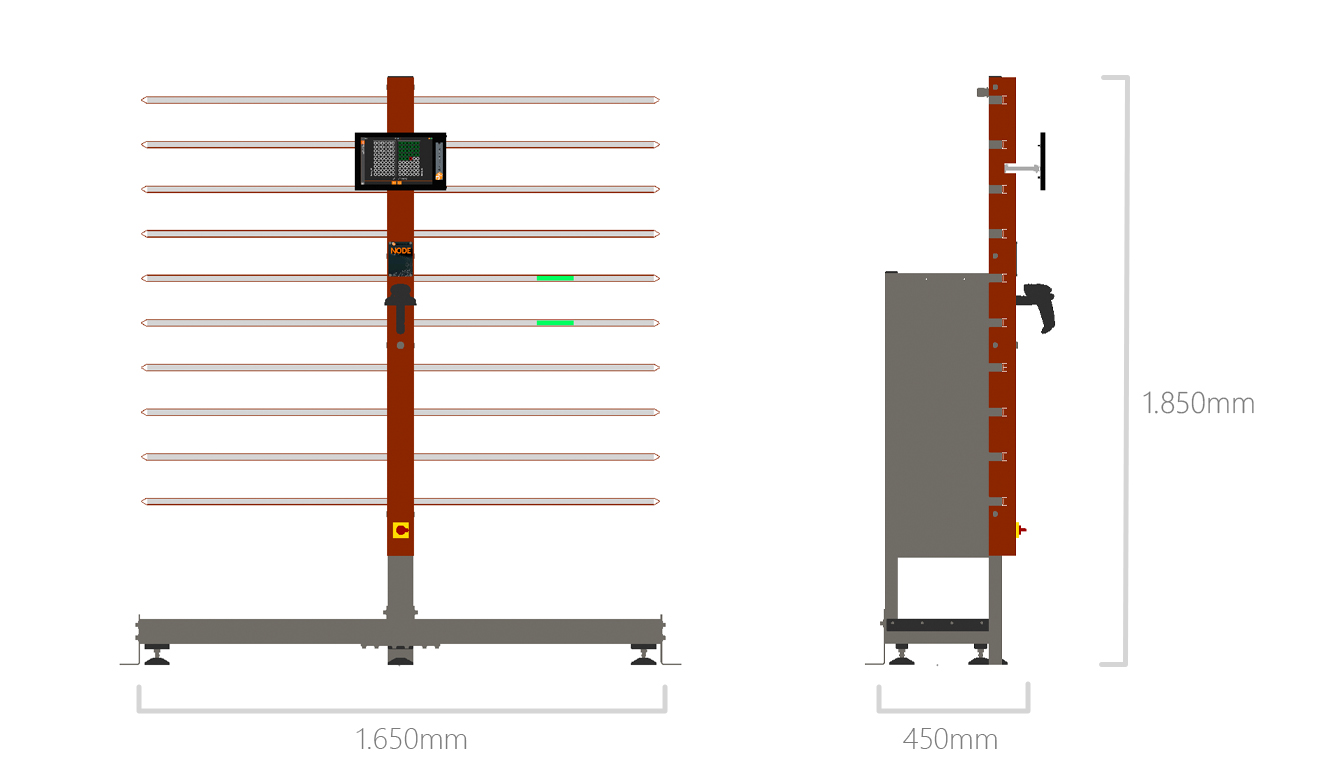

Technical data

The data may vary depending on the version.

-

Technical data

Equipment: PC with touchscreen, barcode scanner, interface to external label printer

-

Dimensions and weight

Height: 1,850mm

Width: 1.650mm

Depth: 450mmWeight: approx. 62kg

-

Connection

Electrical power: 230V / 50Hz, 1 phase, 6A

Network: Ethernet (100/1000 Mbit)