Ultrasonic

Gluing machine

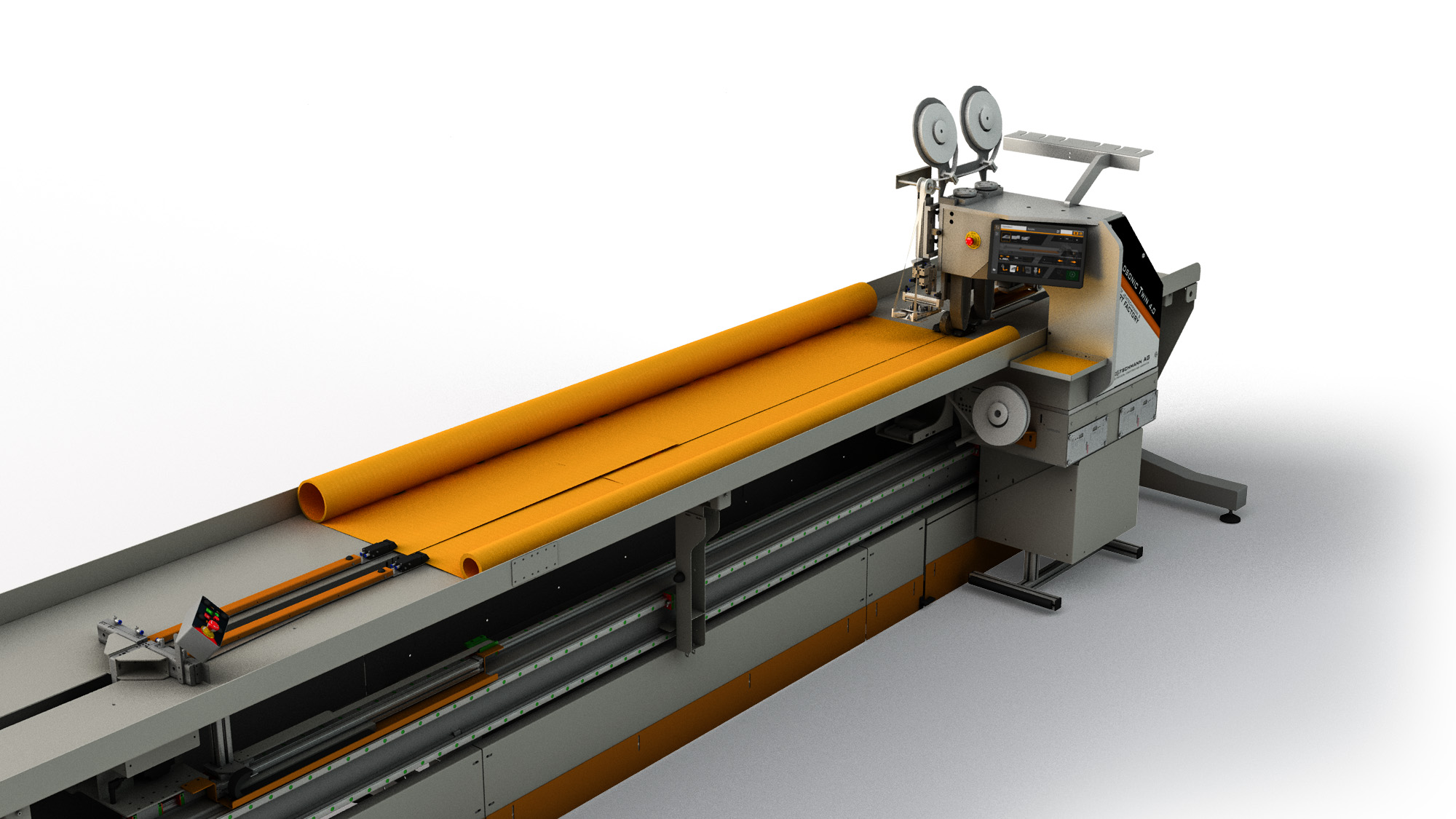

Weldsonic™

Twin

4.0

New Design

Engineered with precision

DESIGN

DESIGN

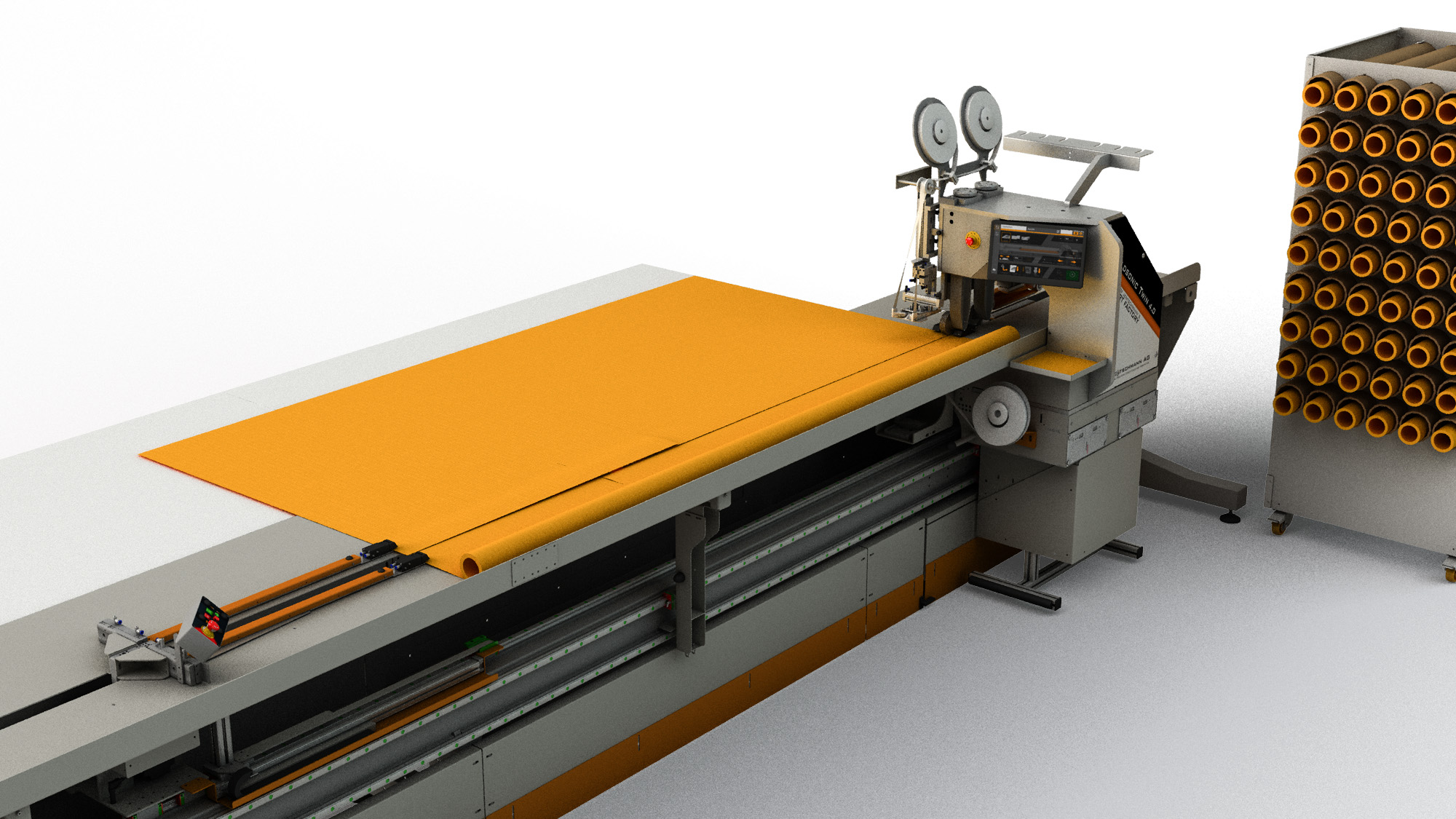

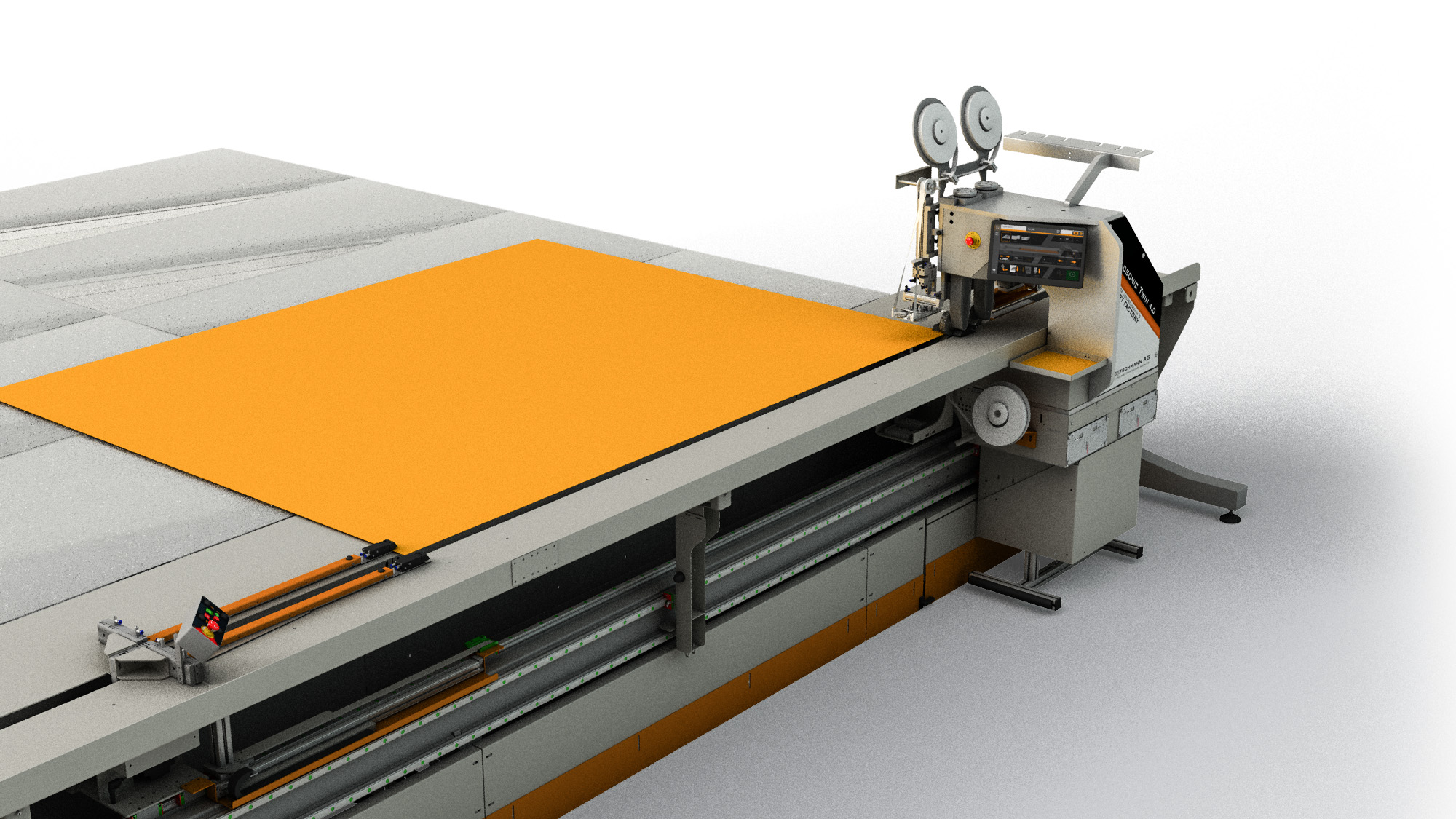

We were able to realize the vision of an even more robust and easier to set-up machine by making fundamental changes to the design of the ultrasonic head. In combination with the newly developed sonotrode generation, this leads to a larger process window for the system.

TECHNOLOGY

HIGHTECH-SONOTRODES

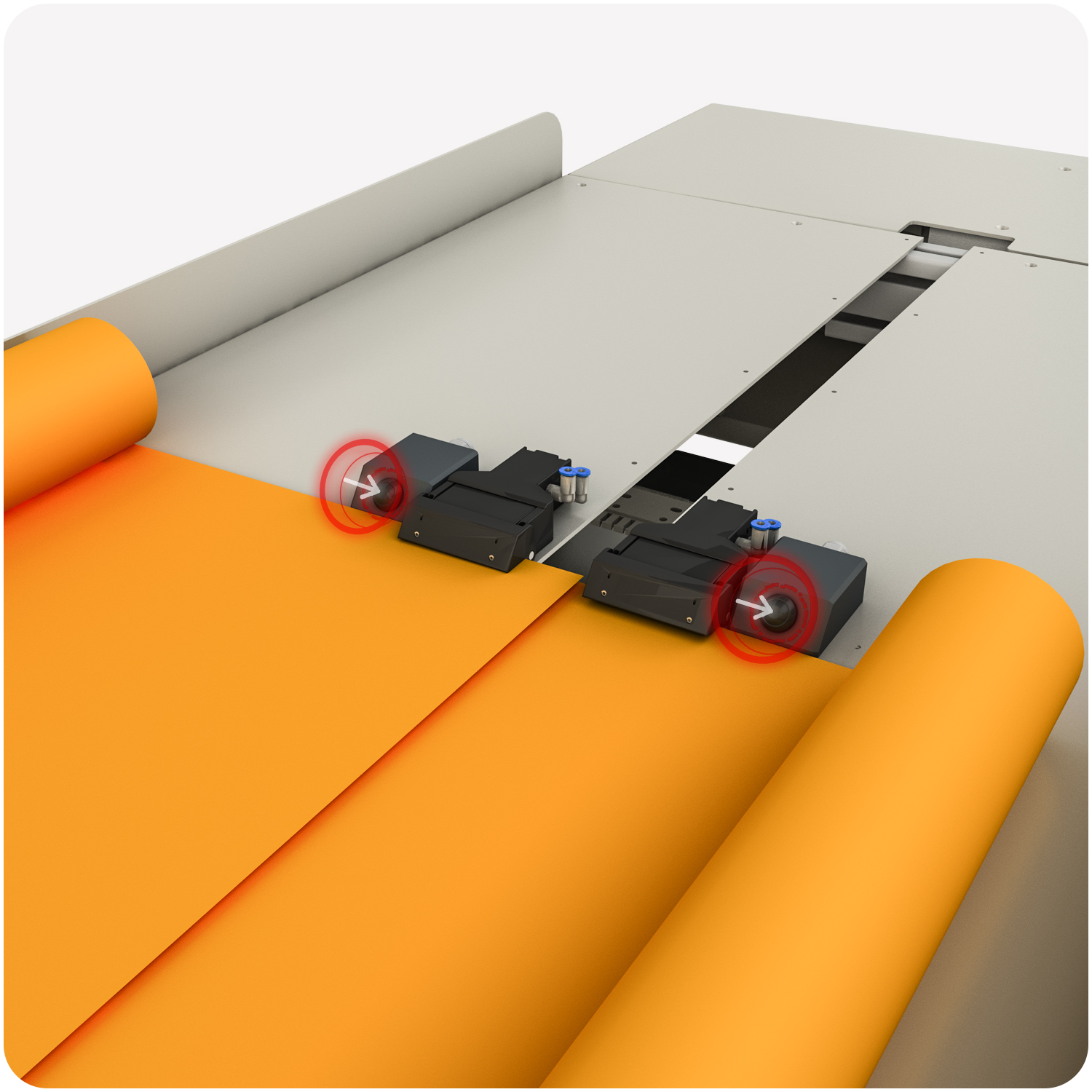

Core components of the Weldsonic™Twin 4.0 are highly sophisticated rotary sonotrodes operating in a frequency range of 35kHz. The self-developed, new sonotrode generation with smooth surface coating and a higher amplitude of 10% has been optimized for its application purpose.

TWO ARE BETTER THAN ONE

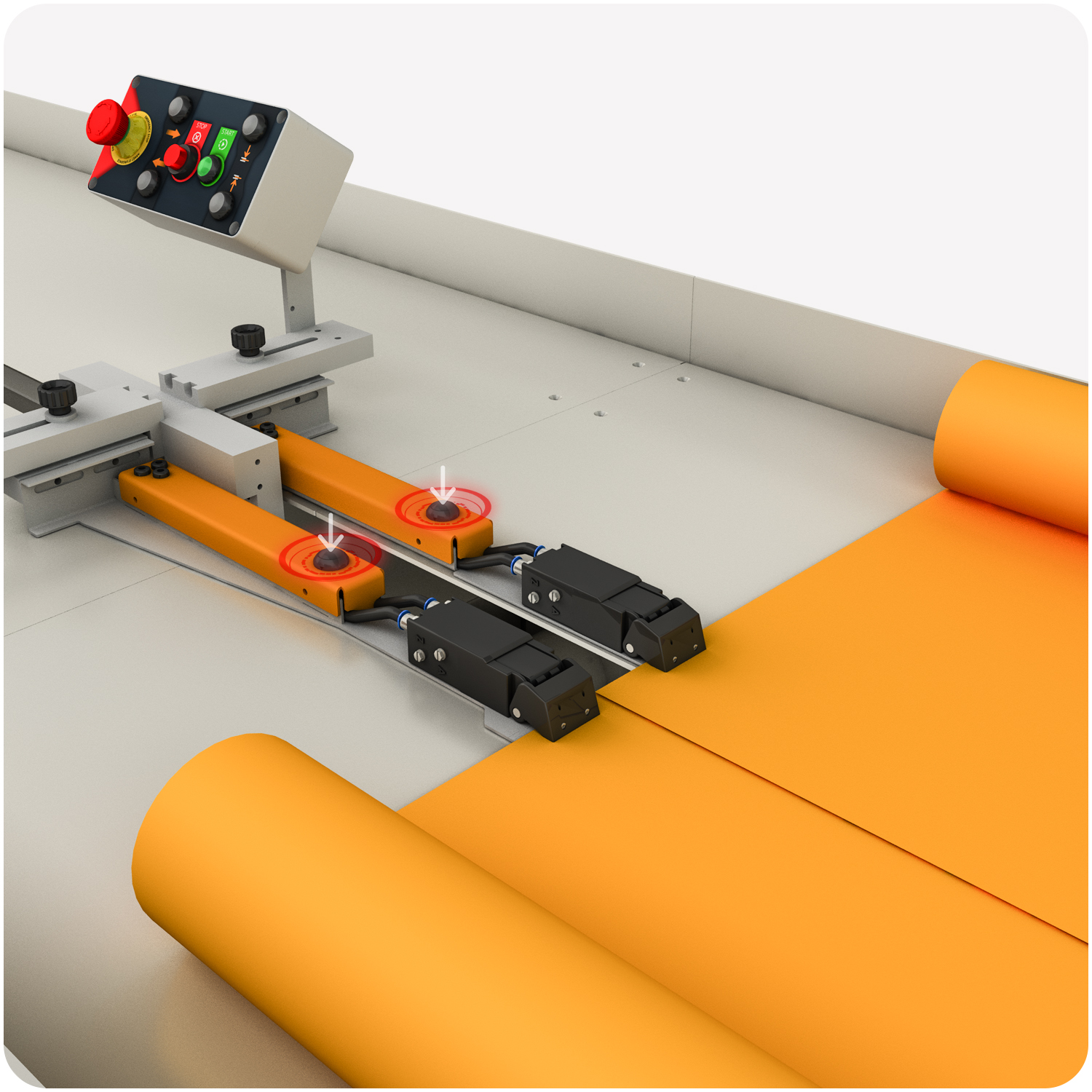

The ultrasonic head works with two anvil/sonotrode units positioned one behind the other. This means that the energy required to activate the adhesive tape can be distributed over two units, making it easier to handle different textiles. Both the anvil roller and the sonotrode are driven separately in order to be able to react to different fabric properties.

MODERN HMI

The machine now features a 13" touch display with 1920 x 1080 resolution in a highly modern UI design.

ELECTRIC CLAMP

AUTOMATIC POSITIONING

The movable clamp positions itself automatically according to the entered seam length, thus optimizing handling times.

DEFINED FABRIC TENSION

After inserting and clamping the fabric, the electric clamp pulls the fabric with an adjustable distance. This stretching distance depends on the length of the fabric and is to be entered in the program as "mm/m".

OPTIMIZED ERGONOMICS

OPTIMALLY ACCESSIBLE CONTROLS

The position and function of individual buttons are thought over and optimized for the regularly used operations of the machine.

Gluing can be so simple

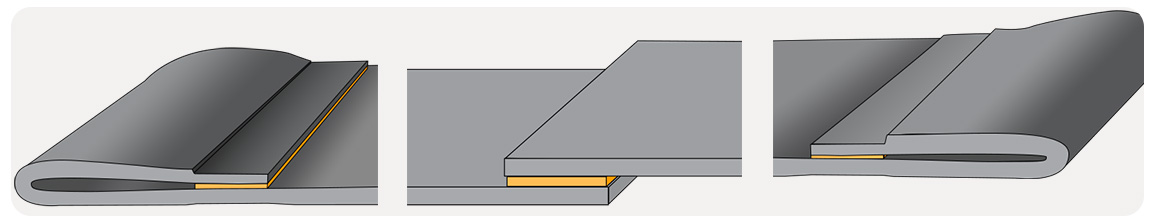

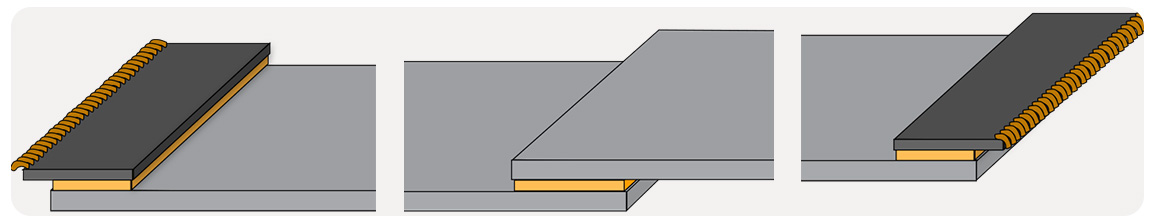

Many big textile sun shading products consist of several fabric panels that have to be joined together after cutting. With ultrasonic technology, this can be done very easily by placing both fabric panels on top of each other and simultaneously inserting a hotmelt adhesive tape between the two fabric layers. By using the two ultrasonic sonotrodes, this adhesive tape is "activated" so that a firm and tight connection is created.

a classic joining process of an overlap seam of 20mm with acrylic fabric

Operations

traditional overlap

UltraSeam™

TERRACE AND BALCONY AWNINGS

Traditionally, terrace and balcony awnings, whether cassette awnings or open awnings, are made overlapping at the joints and the outer edges by hemming.

UltraSeam™ declares war on wrinkles!

A real alternative to the classic traditionally manufactured awning fabric is now available with the UltraSeam™ cloth. The "butt-joint" of the panels by means of highly developed adhesive tapes from the company Gluetex enables significantly better winding behavior, which can lead to a significant improvement in the appearance of the fabric.

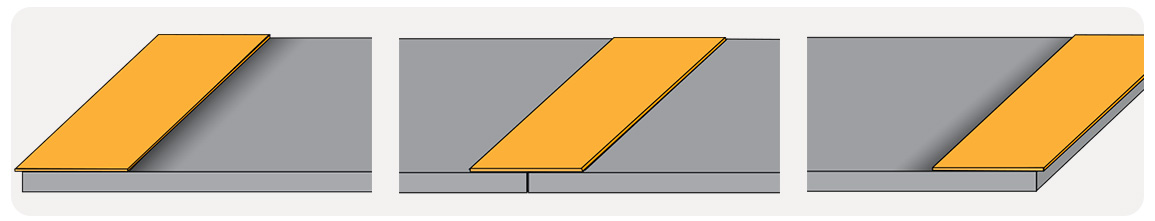

GLASS ROOF/CONSERVATORY AWNING

Both as an on-glass or under-glass awning, glass roof/conservatory awnings are often used as side-guided awnings. Zippers are then applied to the edges of the fabric.

traditionally overlapped with ZIP

UltraSeam™ with UltraZIP™

Variants

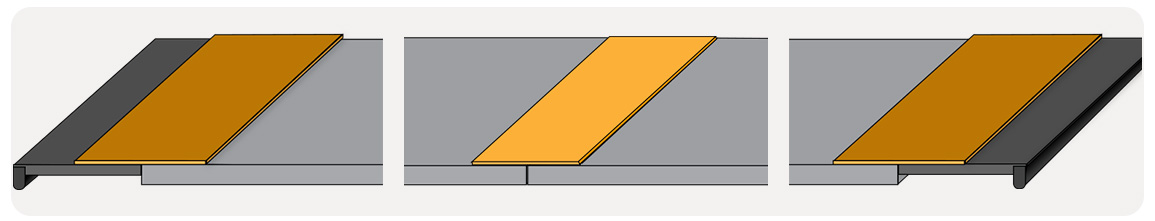

The Weldsonic™Twin 4.0 is configurable in different versions.

4.0 - Workflow

If the ScreenCut / AcrylCut cutting machine is used in combintation with the Material-Handling-System MHS, the panels are delivered to the machine wound on the short side in a MHS trolley. For processing these panels, the Weldsonic™Twin is equipped with an additional side table.

360°

The Weldsonic™Twin 4.0 can also be used as a PVC screen processing machine. In this case, the fabric is processed on all four sides by rotating it step by step through 360° and guiding it into the machine.

The PVC screen panels are primarily cut to size on the ScreenCut and come to the machine in trolleys.

Traditional

In the standard version, the fabric is wound lengthwise and placed in the machine where it is unwound manually from panel to panel.

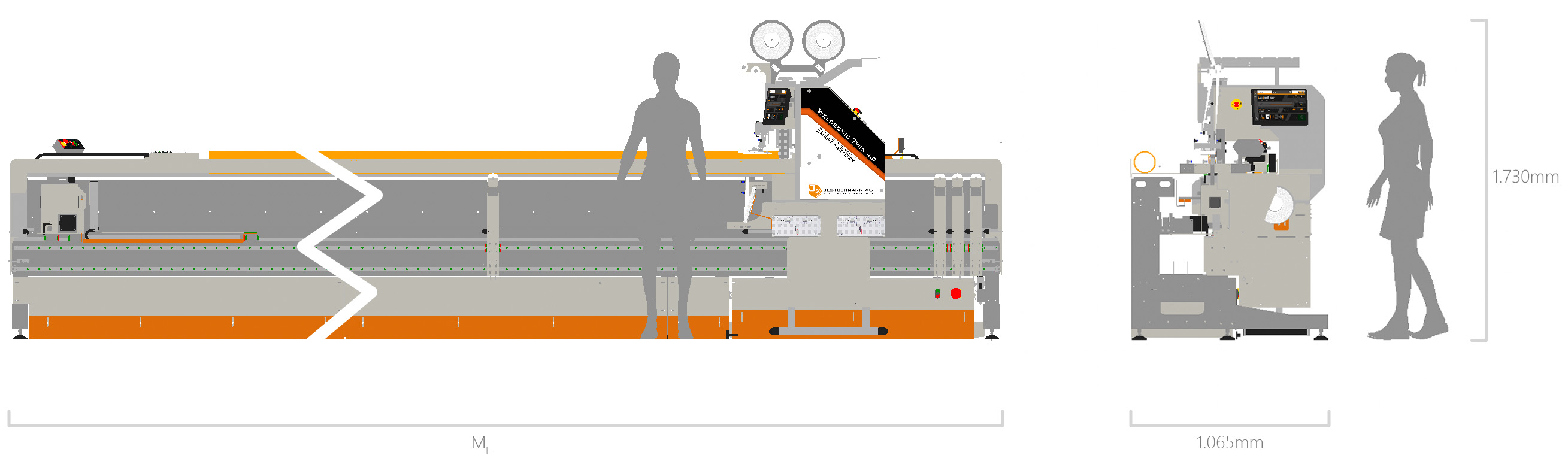

Technical data

The data may vary depending on the version.

-

Operating lengths

Max. operating length: Machine length (ML): 5.000mm 7.200mm 6.080mm 8.280mm 7.040mm 9.240mm 8.460mm 10.800mm 9.545mm 11.880mm 10.275mm 12.840mm -

Technical data

Working speed: average 10 m/min to 13 m/min (depending on the material)

Number of ultrasonic rolling sonotrodes: 2

Number of ultrasonic cutting sonotrodes: 2 (with UltraSeam™ option)

Gluing width: up to 21mm -

Fabrics

Standard version

acrylic and polyester awning fabrics (e.g. Lumera, Tempotest, Orchestra, etc.)360° - version

PVC coated fabrics such as

Screen (e.g. Copaco Serge 600, Mermet Satiné, etc.)

Soltis Perform 92

Soltis Lounge 96 -

Dimensions and weight

Height: 1.730mm (working height 900mm)

Length: variable (ML)

Depth: 1.065mmWeight: 1.285kg to 1.851kg (depending on length and equipment)

-

Connection

Electrical power: 400V / 50Hz, 3 phases, 16A

Pneumatics: Ø 8mm, stable 8bar, dry, oil-free (class 0), 120l/min

Network: Ethernet (100/1000 Mbit)